For the modern manufacturing industries of 2023, horizontal metal cutting bandsaws occupy a valuable niche as the go-to standard for reliable stock cutting to make workpieces ready for machining. Horizontal metal cutting bandsaws are the most consistently accurate, lowest energy use option for stock preparation for machining of high quality products.

Table of Contents

Why do all metal manufacturing industries use horizontal metal cutting bandsaws ?

It doesn’t matter where you look in the manufacturing industries of 2023, but you will find a horizontal metal cutting bandsaw somewhere in the factory space. Horizontal metal cutting bandsaws are a ubiquitous feature of all manufacturing industries for four very good reasons:

- Dependable straight and angled cutting of all types of materials

- Reliable and accurate repeated cutting of metal stock to set lengths

- Cost effective and efficient

- Safe and easy to use

You can use metal chop saws and disc cutters, laser and plasma cutters for cutting, but for simplicity, accuracy, reliability, safety and energy efficiency the horizontal metal cutting bandsaw is the gold standard for cut-to-size material preparation in any workshop.

Why are horizontal metal cutting bandsaws the first step in most machining processes

Manufacturing industries rely on accurate metal cutting bandsaws for the first step of almost every metal product manufacturing process. Cutting stock to exact dimensions ready for further machining and processing is a critical first stage because the accuracy and finish of the metal billet has a significant impact on the efficiency and speed of later machining stages.

What are 4 benefits of using horizontal metal cutting bandsaws in manufacturing industries?

- Very precise kerf reduces loss of material from the cutting process

- Accurate cutting reduces milling overheads to achieve flat surface finishes

- Cutting stock to precise dimensions reduces machining waste when milling or turning to manufacture the finished product

- Horizontal metal cutting bandsaws are energy efficient compared to most other cutting methods

Some manufacturing industries outsource for sawing services, who use metal cutting bandsaws to rapidly supply dimensionally precise, ready-to-machine, stock. Choosing the right metal cutting bandsaw for your manufacturing industry delivers cost saving efficiencies by reducing wastage and saving energy.

Why is the horizontal metal cutting bandsaw the first choice in bandsaws for machining industries?

The horizontal metal cutting bandsaw is a versatile, general purpose cutting machine. Horizontal metal cutting bandsaws cut vertically through the stock, relying on the weight of the cutting assembly to provide sufficient pressure, using a lever arm pulled by an operator, or in the most advanced machines, using hydraulics to control cutting blade pressure through the cut.

What are the three types of metal cutting bandsaw?

- Horizontal metal cutting bandsaw

- Vertical metal cutting bandsaw

- Dual column metal cutting bandsaw

In a horizontal metal cutting bandsaw, a rotating table or vise enables stock to be accurately positioned and clamped for cutting at an angle. When the table angle has been set, multiple cuts can be made easily for production line stock cutting. Gear driven metal cutting bandsaws are a good option for manufacturing industries for repetitive, high performance cutting.

Vertical metal cutting bandsaws have a static cutting blade position, and are only really suitable for cutting sheet materials that are fed through the blade. Round stock and thick plate are difficult to cut safely and accurately with a vertical metal cutting bandsaw.

Dual column metal cutting bandsaws are designed for heavy duty cutting applications, having a pair of vertical columns to guide the vertical cutting movement of the blade through the cut. Dual colum metal cutting bandsaws are very accurate, but also significantly more expensive than standard “scissor-action” metal cutting bandsaws.

High quality metal cutting bandsaws for manufacturing industries

Rong Fu follows the Toyota Production System to ensure we manufacture and deliver the highest quality metal cutting bandsaws possible to our customers. We pride ourselves on our exacting quality standards and the consistent quality and reliability of our horizontal metal cutting bandsaws, which are the product of choice for global OEM machinery brands.

As a longstanding metal cutting bandsaw manufacturer with extensive manufacturing and marketing experience built over decades of satisfying our customer requirements, we offer an extensive portfolio of off-the-shelf metal cutting bandsaws of all types and capacities, from our smallest portable models through to high capacity, feature-rich single column machines.

Accessories that can be used to customize our horizontal metal cutting bandsaws

- Single roller stock stand – for stabilizing long stock while cutting to length

- Roller table – for controlling heavy stock (available up to 250kg capacity)

- Halogen light – improves visibility in the working area

- Hydraulic blade tension meter – consistent blade tension and improves blade life

With options for gravity feed, pull-down or hydraulic operation and swivel heads for miter cuts, the Rong Fu horizontal metal cutting bandsaw range is extremely versatile. Our semi-automatic horizontal metal cutting bandsaws are a popular choice for manufacturing industries needing to cut a large number of stock lengths rapidly as the automatic return of the saw bow the the raised position ready for the next cut reduces operator fatigue.

Horizontal metal cutting bandsaws to suit all types of manufacturing industry

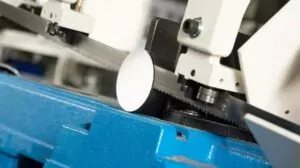

The versatile Rong Fu RF320 gear drive horizontal metal cutting bandsaw pictured above is an excellent entry level machine for a medium sized workshop needing to supply a wide range of parts cut to length for any manufacturing industry. The RF320 is a very flexible machine that can be supplied with optional accessories to customize it for specific uses.

The Rong Fu RF320 horizontal metal cutting bandsaw offers flexibility by design

- Cut solid bars, plate, steel tube, & pipe

- Swivel head for variable cutting angles

- Includes tooth selection chart on machine for cutting reference.

- Motor stops when button released for increased safety

- Ergonomic working height of 950mm

- 1” cutting blade & carbide guide for improved cutting surface finish & efficiency

- One-piece casting & one time CNC machining for rigidity & precision

- One-piece full blade cover meets CE safety standards

- Integrated coolant fluid collection

- Chip pan keeps coolant fluid from leaking Into working area

- Variable speed (optional)

- Semi auto saw bow (optional)

- Hydraulic vise (optional)

- Compatible with full range of Rong Fu accessories

If your needs are more heavy duty, or you require a more highly automated machine with hydraulic downforce, then our RF420 horizontal metal cutting bandsaw is the next step up from the R320, with a similar array of impressive features and the addition of hydraulic cutting to reduce operator fatigue.

Rong Fu manufactures metal cutting bandsaws for every possible manufacturing industry application. Manufactured to our very strict quality control standards to ensure reliability and give you peace of mind. Contact us to discuss how we can supply metal cutting bandsaws and accessories that meet your needs no matter how small or large your requirement.