Making the right choice between the different types of metal cutting bandsaws is vital to get the most out of your investment. This article examines the efficiency and durability of gear drive metal cutting bandsaws, highlighting their advantages for heavy-duty tasks and comparing them with belt drive alternatives.

Table of Contents

Why are gear drive metal cutting bandsaws used for heavy duty cutting?

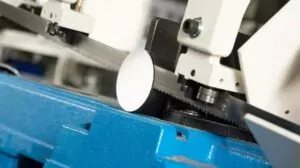

Gear drive metal cutting bandsaws, like the Rong Fu RF-320 pictured above, are more complex than belt drive metal cutting bandsaws, and may generate more noise and vibration. They are, however, the first choice for most industries that need to carry out heavy duty metal cutting, and for production line fabrication of large numbers of repetitive parts.

There are two reasons why gear drive metal cutting bandsaws are commonly used in demanding industrial applications as well as smaller workshops that perform a lot of repetitive cutting work:

- Gear drive metal cutting bandsaws can cut rapidly, even through hard materials.

- Gear drive metal cutting bandsaws require minimal operator maintenance and adjustment compared to belt drive metal cutting bandsaws.

We know that fabricators prefer heavy duty metal cutting bandsaws, and the biggest impact on metal cutting productivity is machine downtime. Gear drive metal cutting bandsaws reduce machine downtime as there is no need for belt changes or tension adjustments. Simply set up the machine and keep cutting stock until you have completed the project.

How do gear drive metal cutting bandsaws differ from belt drive metal cutting bandsaws?

Belt drive metal cutting bandsaws use belts on pulleys to drive the saw. To change the speed an operator manually moves the belt to different positions on the pulleys to change the ratio of motor speed to drive pulley speed. A gear drive metal cutting bandsaw uses a gear shift and toothed gears for the same purpose.

Pulley belts will tend to slip if the saw encounters high cutting resistance, and this reduces the cutting power of a belt drive metal cutting bandsaw under high loads, slowing down cutting time, and promoting belt wear. This increases the maintenance requirements of belt drive metal cutting bandsaws compared to gear drive metal cutting bandsaws.

Comparison of direct drive & belt drive metal cutting bandsaws

| Gear Drive Metal Cutting Bandsaws | Belt Drive Metal Cutting Bandsaws |

| Direct drive of cutting action through motorized gearbox connected to saw | Indirect drive of cutting action using belts and pulleys to connect the motor to the saw |

| Number of speeds limited by gearbox design | Number of speeds limited by pulley configuration |

| Direct drive eliminates mechanical slippage during cutting | Drive belts designed to slip under heavy loads |

| Very low maintenance once set up for a task | Requires operator monitoring to maintain correct tension and correct for belt slippage |

| Direct drive, heavy duty gearing can be noisy and transmit vibration through machine | Indirect belt drive tends to be quieter and reduce vibration transmission |

It’s not all bad for belt drive metal cutting bandsaws – because pulleys can be fitted with a range of diameters and configurations you usually have more choice of speed settings than you can achieve with a gear drive metal cutting bandsaw. The gear drive metal cutting bandsaw has a limited number of gears as they are built into the gearbox mechanism.

Variable speed gear drive metal cutting bandsaws

For ultimate flexibility Rong Fu manufactures DC motor variable speed gear drive metal cutting bandsaws, like the Rong Fu RF-270 shown here. The DC motor can be adjusted to vary the speed at each of the low and high fixed gear settings for fine tuning of your cutting speed.

The fixed gear sets of gear drive metal cutting bandsaws are selected to enable slow and fast cutting, so the reduced number of speed ratios is not a limiting factor. Fixed speeds are a minor consideration for many heavy duty and repetitive cutting tasks. You can, however, have it all with a DC motor variable speed bandsaw!

Rong Fu gear drive metal cutting bandsaws

Rong Fu is a long established metal cutting bandsaw manufacturer of gear drive and belt drive, manual and semi-automatic metal cutting bandsaws. We manufacture metal cutting bandsaws to Toyota Production System standards for high quality defect-free results and rapid shipping times.

Our gear drive metal cutting bandsaws have options for gravity feed, hydraulic or pull-down operation and swivel heads for miter cutting. For rapid, repetitive cutting, semi-automatic gear drive metal cutting bandsaws raise the saw bow after each cutting cycle to the ready position. This reduces operator effort and speeds up production throughput.

Our 2023 gear drive metal cutting bandsaws

Rong Fu gear drive metal cutting bandsaws range from the small, portable 4” Rong Fu RF125 metal cutting bandsaw in our 4”-8” range to the RF420 hydraulic cylinder gear drive metal cutting bandsaw (pictured above) in our 9”-20” capacity range of saws. The RF420 is packed with features to suit the demands of the busiest and most demanding workshop tasks.

12 Features of the Rong Fu RF420 gear drive metal cutting bandsaw

- Swivel head for varied cutting angles up to 60 degrees

- Tooth selection chart on machine for cutting reference

- Variable speed control – standard 2-speed motor

- Suitable for cutting standard solid bars, plate, steel tube, & pipe

- Hydraulic cylinder controls feeding volume & provides stable cutting

- Working table slides back & forth conveniently by adjusting only two bolts

- Easily adjust swivel position to desired angle without moving workpiece

- Rapid vise action and positioning for clamping all sizes of workpiece

- Chip pan keeps coolant fluid separate from work area

- Variable speed (optional)

- Semi-Auto saw bow (optional)

- Hydraulic vise (optional)

Contact us to discover how the comprehensive and feature rich range of Rong Fu metal cutting bandsaws includes models to meet your every possible need. All our machines are manufactured to the highest possible quality control standards for your peace of mind, and to guarantee excellent performance straight out of the box!