Rong Fu mill drill machines offer a flexible and versatile solution for gang milling, form milling & fly cutting projects

Table of Contents

Gang milling, form milling and fly cutting are expert milling techniques that you can achieve on your Rong Fu mill drill machine. Gang milling enables multiple cuts to be made in a single pass, form milling is excellent for cutting contours, and fly cutting is a flexible technique that also enables very fine finishing when face milling.

What are the key features of gang milling, form milling & fly cutting?

- Gang milling enables multiple slots or grooves to be cut at the same time

- Form milling cuts profiles, contours and irregular geometries

- Fly cutting eliminates run out when used for face milling

For most cutting tasks, cutters are designed, shaped, and named for the specific task, and you want to use the right cutting tool for the job. Gang milling, form milling and fly cutting are no exception to this rule, but add flexibility to how you achieve your desired profile and finish.

Gang Milling

Gang milling is a cutting technique used for making simultaneous cuts of different depths along a workpiece. This is done by mounting two or more cutting wheels of different diameters on a single shaft. This is normally used to cut square edged profiles with different slot depths, but by using form or contour cutters it is possible to create almost any profile using this technique.

What are three features of gang milling?

- Gang milling is quicker than making multiple cuts and changing cutting tools

- Good for mass production where cost efficiencies are important

- Cutting speed for gang milling is limited by the largest diameter cutter in the set

Side milling cutters are most commonly used for gang milling. If the cutters are used to mill two sides of a workpiece simultaneously without milling between the cutters then this technique is called ‘straddle milling’ rather than gang milling. Side milling cutters of different diameters, widths, and profiles are stacked on the arbor to create the desired profile, only limited by the geometry and material of the workpiece

Form Milling

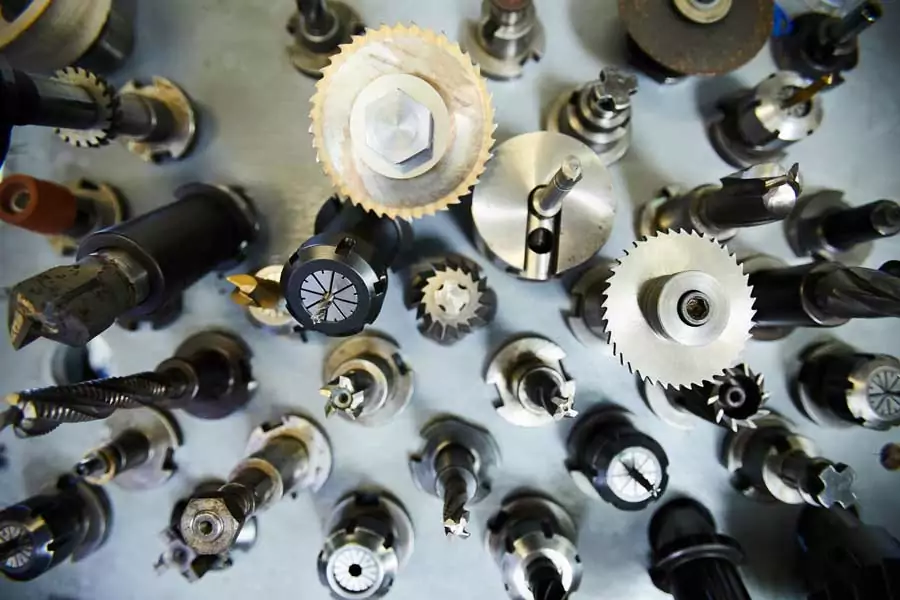

Formed milling cutters are shaped specially for specific cutting profiles. The examples in the picture above are rounded profiles. Form milling uses special cutting tools with their geometry shaped to cut specific contours in the workpiece. When you use a form milling cutter, the material removed from the surface of the workpiece creates a contour that matches the shape of the cutter.

What are 3 features of form milling?

- Cutters are formed into shapes for cutting specific matching profiles in the workpiece

- Speed and feed need to be reduced compared to plain milling tools

- Commonly used for round, convex and concave milling

Form milling cutters can be manufactured in irregular shapes and profiles, which makes them useful for cutting irregular forms or contours, but are most often used for cutting convex, rounded, or concave slots and grooves on a horizontal milling machine. To achieve the best results and surface finishing it is usually necessary to reduce the cutting speed and feed by approximately 30% compared to plain milling with equivalent size tools.

Fly Cutting

A fly cutter is a flexible tool that is formed by grinding a single point cutter bit to a required shape and then mounting the cutting bit on a bar, holder, or specially designed fly cutter arbor. A ground point fly cutter can be sharpened many times for extended use. Indexed cutting inserts can be fitted to a fly cutter arbor instead of grinding your own fly cutter if you want to save time.

What are 3 features of fly cutting?

- Good for fine finishing when face or end milling

- Fly cutters are cheap to manufacture

- Cut at a slower RPM to achieve the best finishes

Fly cutters feature a single cutting point working on the same principle as the face mill, but with a slower cutting speed due to having only one edge and requiring reduced RPM for optimum results. Fly cutters are sometimes used for face milling and end milling because they have no runout, and can be used to achieve very fine surface finishes.

Setting up your mill drill machine for gang milling, form milling & fly cutting

As is always the case when you set up your mill drill machine, you will get the best results from gang milling, form milling and fly cutting if you follow some basic steps. These steps help you take care of your machine, ensure the cutting surfaces are properly indexed, and protect your tools and workpiece from distortion or damage.

Check these three useful guides to setting up your mill drill machine

- Follow proper clamping procedures for your mill drill machine

- Index your mill drill machine to ensure precision

- Know your general milling & feed speeds

When form milling, and fly cutting remember that you will probably need to reduce the cutting speed by up to 30%, and for gang milling adjust the speed to the slowest cutter in the stack. Always remember to use the correct lubrication and coolant for your mill drill machine.

Rong Fu Mill Drill Machines For Gang Milling, Form Milling & Fly Cutting

Rong Fu mill drill machines include several models that are well suited to gang milling, form milling and fly cutting. Out of our comprehensive range of mill drill machines, the RF-45 gear head mill drill machine shown above features a swivel head that can be rotated 90 degrees, making it ideal for gang milling and form cutting of horizontal and vertical surfaces.

The gear head RF-45 is a versatile 6-speed mill drill machine, with powered down feed and digital readout options available. Perfect as a primary machine for a small workshop or as a secondary machine for flexible form cutting and contouring work.

Contact us to find out more about the full range of Rong Fu mill drill machines and to discover how we can meet all your mill drill machine requirements. Every one of our mill drill machines and metal cutting bandsaws are constructed with total quality control as part of our Toyota Production System process. You can rely on every Rong Fu product to be durable and trouble-free.