In today’s metalworking and mechanical workshops, mill drill machines have an important role to play in maximizing productivity and minimizing waste. Rong Fu manufactures a range of fully featured mill drill machines to match the requirements of any workshop, no matter the scale of operations.

Table of Contents

Do You Need a Mill Drill or a Drill Press?

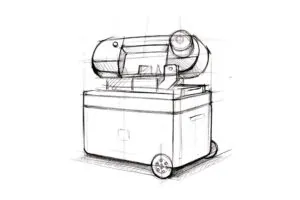

The Rong Fu RF-40 Mill Drill pictured above is a typical example of a compact, bench-mounted gear driven mill drill machine, well suited for years of reliable, accurate service. Workshop managers have many factors to think about when choosing a mill drill or drill press, depending on their specific circumstances, so being able to select from a comprehensive range of mill drill machines is a significant benefit.

Mill drill machines can drill like a drill press as well as performing milling functions. If budget or space are limited in a small workshop, a mill drill machine provides more flexibility than a drill press. A mill drill reduces the space requirement compared to having to install two machines, and can save on costs as well.

What are the key features of workshop mill drill machines?

- Milling & drilling functionality

- Axis of travel dimensions

- Spindle power & speed

A mill drill machine can mill stock and also drill like a drilling machine or drill press. Stand alone milling machines are not designed for repetitive, rapid drilling, so although you can use them for drilling they will not be as quick or as efficient as a mill drill machine. The dual functionality of a mill drill machine is a key feature that makes it a very attractive tool for any workshop.

The second feature that is an important consideration for workshop managers is the dimensions of the axis of travel of the mill drill machine. Generally, the larger machines have longer X, Y and Z axis capacity to enable bigger projects to be milled and drilled.

Spindle power and speed are the third feature that needs to be evaluated. Routine cutting in softer materials is less demanding than milling and drilling in stainless steel, hardened steels and cast iron. If you work with mild steels, brass and soft alloys a smaller, belt driven machine is perfectly adequate. For harder materials a larger gear driven machine may offer better milling and drilling performance.

How precise are workshop mill drill machines?

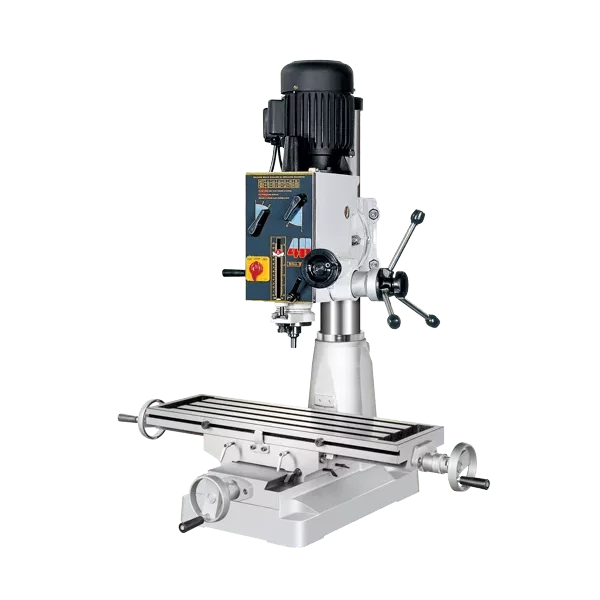

Mill drill machines come in both benchtop and freestanding versions. A freestanding machine like the Rong Fu RF-400 pictured above, with custom-built table and support, offers improved precision due to the rigid design. A benchtop machine needs to be securely fixed to a suitable workbench to achieve the same accuracy.

High speed machining with small tools works well for delicate and small components, but you need low speed torque for heavy cutting. For precision work look for a mill drill that has sufficient gearing and speed control for high speed operation as well as the power for low speed torque. The RF-400 can be configured to operate at up to 3,000 rpm at 60Hz, with a 1.5Hp motor offering plenty of power for any task.

What other features can you expect from today’s workshop mill drill machines?

User friendly, intuitive controls with easy to read settings, and digital displays on higher end machines make it easier to operate modern mill drill machines. Safety features are essential, including emergency stop buttons and safety interlocks to prevent injuries by opening cases when the machine is operating.

For longevity and smooth cutting, integrated cooling and lubrication of the cutting area and easily accessible, clearly marked lubrication and maintenance points on the mill drill machine are also desirable features. Powered downfeeds and working lights reduce operator fatigue and increase efficiency.

Rong Fu mill drill machines deliver precise, reliable performance

Rong Fu is an OEM mill drill machine manufacturer, working to Toyota Production System (TPS) standards to offer a portfolio of highly reliable mill drill machines to suit any requirement, from small workshops to industrial production lines.

Contact us to discover our capabilities and capacity to supply modern, high quality mill drill machines that will more than satisfy the demands of your customers for efficient, reliable performance.