Metal cutting bandsaws are standard equipment for machine shops and metal manufacturing across a wide range of industries. The metal cutting bandsaw is such a common tool in the work place that most people probably don’t give a second thought to how it was manufactured and who manufactured it – even though these are critical considerations for quality and reliability!

Table of Contents

What is the metal cutting bandsaws manufacturing process?

Smooth operation and cutting quality are the products of excellence in design and quality management during the metal cutting bandsaw manufacturing process. As a trusted OEM metal cutting bandsaw manufacturer, we keep our quality and production processes under complete control every step of the way from initial design work through to shipping to our customers.

Rong Fu uses the Toyota Production System (TPS) to ensure that we don’t become complacent in our metal cutting bandsaw manufacturing, and can always pick up newer and better manufacturing and inspection methods to maintain our high standards.

In-house Research & Development

Rong Fu is a vertically integrated company, from in-house R&D through to production and packaging. This enables us to be very flexible in our design and innovation while keeping to strict quality standards.

For new components our R&D department completes the 3D designs for our metal cutting bandsaw components and then passes them on to our workshop for CNC machining. Required changes to assembly processes and quality checks are also reviewed at this time by the quality team.

If customers request changes to specifications or control panel layouts and features these will also be reviewed by our R&D department. We will then review, design and implement any software, hardware or accessories changes for operational safety and efficiency before passing to production for implementation.

Our skilled CAD technicians work on our metal cutting bandsaws to generate production templates, jigs and processes. We also modify existing designs to meet customer requirements for control panels and optional features.

Inventory Management

Our parts warehouse is designed to provide easy access to components for production technicians through our clear labeling system and the systematic location of components. At the start of each shift the production technicians for each assembly cell visit the parts warehouse and collect all of the components they require for that day’s production on mobile carts.

They follow clear parts lists for their station which are provided by production management for each production cell. The components carts are then stored right next to the production cell where they are required to provide easy access and more efficient production by optimizing parts access during assembly.

What is the Toyota Production System?

Toyota’s Production System (TPS) enhances efficiency and quality, minimizing waste. It integrates ‘Jidoka’ (smart automation) and ‘Just-in-Time’ production for optimal workflow. TPS is foundational to ‘Lean Manufacturing’.

Electrical Assembly

The control boxes and software are designed and manufactured in house so we can customize designs to suit customer needs and regulations of different markets especially concerned with safety regulations

We assemble electrical components of our metal cutting bandsaws in a designated area of our manufacturing facility. Electrical panels and control equipment are built to TPS ‘Just in Time’ principles for maximum efficiency. Every electrical control and operational component is checked and tested before installation.

Casting & Machining of Parts

Cast parts need to be finished and milled before assembly, and subjected to the same quality checks as the rest of the production process. We design and manufacture our own castings for the structure and key components of our bandsaws. These castings are then precision CNC machined in our own machine shop so that we maintain complete control over production quality of these vital components.

Surface Finishing & Painting

Our painting and finishing processes are isolated from the assembly line for health and safety reasons with their own ventilation and extraction systems. This also eliminates potential dust contamination from the production process, improving the finish and extending the service life of coatings.

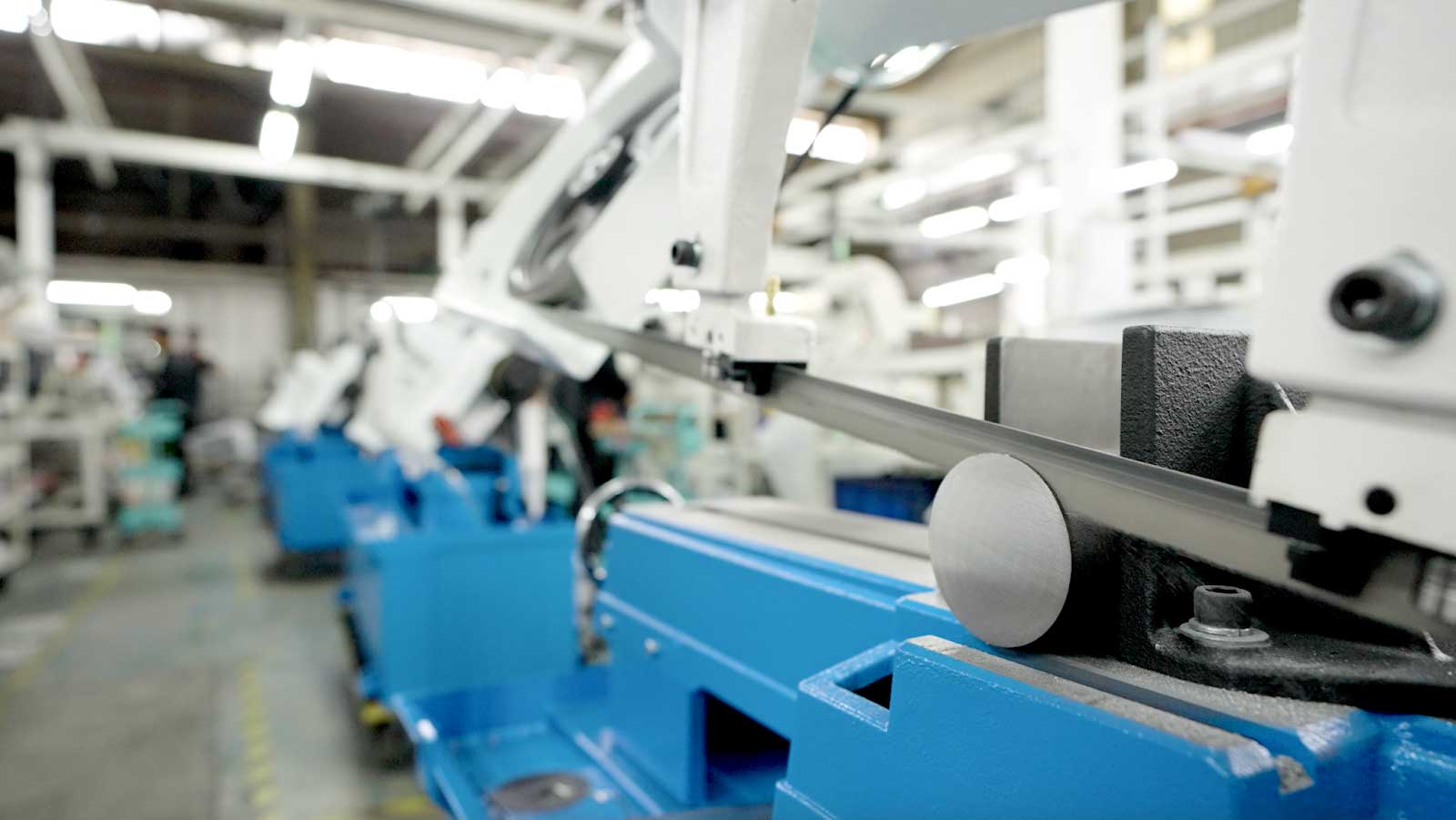

Metal Cutting Bandsaw Assembly

We make full use of the TPS to improve manufacturing efficiency, ensuring every component and tool is at the right place at the right time on the assembly line. The machine being assembled is set on a mobile trolley at an appropriate height to be easy for workers to handle without risk of back injuries and to comply with workplace health and safety best practices.

There are separate stations for each step of the assembly process and our technicians maintain the tools required at each assembly stage on tool boards, ready to hand. We also have specialized assembly jigs where needed that ensure standardized assembly and guarantee quality. We move heavy components by overhead cranes along tracks that lead directly to the appropriate assembly stages.

Metal Cutting Bandsaws Quality Testing

There are two stages at the end of assembly to verify quality standards before packaging. The first stage is carried out by the most experienced technicians and includes the following tests:

- Electrical Safety Test

- Operational Vibration Test

- Functional Test

- Blade Alignment Verification

- Cutting Tests

Once the final cutting test is completed the production technician notes down the results on the test piece and this piece is provided to the customer with the machine as a verification of cutting tolerance.

In the second stage of the process a representative from our dedicated quality team runs through a quality checklist with the production technician. This is to make final visual inspections of the machine and also to ensure that all of the quality checks were carried out and the results noted correctly on the checklist. The checklist for each machine is also provided to the customer as a final verification.

| Testing Cutting Accuracy |  |

| Measuring Cutting Accuracy |  |

| Metal Cutting Bandsaw Perpendicularity Check |  |

| Testing Metal Cutting Bandsaw Operational Vibration |  |

| Motor Current Stability Testing |  |

| Bandsaw Speed Measurement |  |

Can we Customize our Bandsaws?

Many clients require customized control panels to suit their local regulatory and customer preferences. We are experts in customization to match OEM requirements for global compliance.

Rong Fu offer options for vise configurations, hydraulic tensioners and down feeds, belt or gear-driven gearboxes, and lubrication systems. We also supply a full range of customer accessories for our entire range of metal cutting bandsaws, from the smallest, portable bandsaws through to our heavy duty hydraulic and column metal cutting bandsaws.

Quality is a Rong Fu Metal Cutting Bandsaw

We supply metal cutting bandsaws that perform very accurate, and reliable straight, angled and repeated cutting of metal stock. All our products are safe, easy to use, efficient and cost-effective. These are the core requirements of metal cutting bandsaw manufacturing, and once these are met, we add further value through customization options.

Our manufacturing process is only part of our story, and is seamlessly integrated into careful testing, packaging and shipping. Every Rong Fu metal cutting bandsaw reaches our customers on time, in perfect condition, and ready to cut, straight out of the box. Contact us to discover metal cutting bandsaws and accessories that meet your needs no matter what your requirement.