A step by step guide to using your mill drill machine safely

Table of Contents

Mill drill machines are designed for rapid and accurate milling and drilling of metals. Mill drill machines can be dangerous if not used properly, and it is the responsibility of the operator to make sure that you operate your mill drill machine safely.

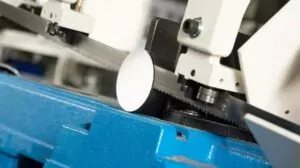

High quality mill drill machines, like the Rong Fu RF-500 pictured above, have features that make them safer to use, but it is always necessary to take care that you follow all safety guidance to protect yourself and others. The safety tips here apply to all mill drill machines.

What should you know before you start using a mill drill machine?

- Carefully read the owner’s manual

- Ensure that you understand the instructions for operating the mill drill machine

- Take relevant training before you start operating a mill drill machine.

- Take time to set up your mill drill machine correctly

What are four health & safety topics for mill drill machines?

To operate a mill drill machine safely, you need to have a good understanding of health & safety, and know how to troubleshoot your mill drill machine to reduce the likelihood of potentially dangerous situations. There are four main health and safety topics you need to familiarize yourself with.

- Essential health & safety basics with your mill drill machine

- Getting your mill drill machine ready for work

- Safe operation of your mill drill machine

- Handling & changing cutting tools

1. Essential health & safety basics with your mill drill machine

- Wear certified safety glasses

- Wear appropriate hearing protection

- Never leave your mill drill machine while it is operating

Wear safety glasses and hearing protection when operating your mill drill machine. Cutting creates chips and splinters that can damage your eyes, and over time the noise of cutting can damage your hearing. You should also never leave your mill drill machine running unattended!

- Do not wear jewelry or loose clothes

- Make sure your mill drill machine has a start/stop button you can reach easily

- Know the location of your mill drill emergency stop button (e-stop)

Jewelry, loose clothing or long hair can get caught in the moving cutter. Remove jewelry, wear close fitting overalls and if you have long hair tie it back or wear a hair net. Know the location of the emergency stop button for your mill drill machine, and ensure other people working around you know where it is too.

2. Getting your mill drill machine ready for work

- To avoid injuring your hands, move the work table away from the cutter to set up work

- Ensure both the work piece and cutter are securely clamped before starting to cut

- Check that work is mounted squarely

Cutting tools should be very sharp, so it is a good idea to move the work table away from the tool to set up your work piece. Ensure you have clamped your workpiece correctly before cutting, and that the cutting tool is securely and correctly fitted into the spindle. Make sure that when you clamp your work it is level and square to the table.

- Use lifting equipment to move heavy work to or from milling machines

- Clamp work in a vise that is securely fixed to the table

- Use proper hand tools to make adjustments

If you are milling large items, don’t forget to handle them safely and use lifting equipment if necessary to avoid unnecessary strain. You must make sure that your work is not only clamped securely but also that the vise is properly attached to the table. You must use the proper hand tools to make sure that clamps and cutting tools are adjusted to the correct torque values.

3. Safe operation of your mill drill machine

- Mill the largest surface first

- Change cutting compounds periodically

- Keep hands, brushes and rags away from the revolving milling cutter

Start cutting the largest surface first when using your mill drill machine. This makes the cutting action more stable and reduces vibration. When cutting irregular objects make sure you follow good clamping procedures to reduce the likelihood of distortion or damage. Keep all loose objects well away from the revolving cutter as they can be dragged in and cause injury.

- Keep the floor around the mill drill machine free of oil and cutting waste

- Keep working surface clear of scraps, tools and materials

- Use a vacuum, brush or rake to remove cuttings when the cutter has come to a complete stop

Keeping the work area clean and tidy and clearing up scraps and cuttings regularly is essential for safe operation of your mill drill machine. It is easy to slip on oil and cutting liquids. Only clean the machine when it has come to a complete stop and you have turned off the power.

4. Handling & changing cutting tools

- Keep cutters sharpened correctly and in good condition

- Remove cutting tools from the spindle when cleaning the machine

- Turn the power off before changing cutters

- Hold milling cutters with a cloth or wear gloves to avoid being cut

The quality of your milling and drilling depends on using tools that are sharp and in good condition. Because they are very sharp, remove them before cleaning the machine or it is easy to cut yourself. Always turn off and isolate the electrical power when changing cutters, and hold them with a cloth or wear gloves to avoid cuts when handling them.

Safety Is A Quality Issue

When looking for a mill drill machine, the quality of design and construction is very important in making it as safe as possible to use, as well as to ensure you get the best possible performance and the cleanest cuts from your machine.

As a leading mill drill machine manufacturer, we are proud of our quality control in manufacturing and our attention to detail in the design of our mill drill machines, which include safety features that help protect you while you work. Contact us to find out more.