How to optimize mill drill machine speed & feed for general milling & drilling tasks

Once you have set up your mill drill machine, selected the right cutting tool for the job, correctly clamped your workpiece and indexed your mill drill machine, you only need to work out your milling speed and feed to be ready to start milling and drilling.

Table of Contents

Why is it important to use the correct milling speed & feed?

When you start using your mill drill machine, you might not have a good idea of the correct milling speed and feed settings to use. You will be wondering about feed speed and cutting speed, and how these will affect your work.

What are four key questions you need to ask yourself to decide milling speed & feed?

- What spindle speed to use

- What size of cutter

- How deep you can cut in one pass

- How fast to move the table

The answer to these questions depends on three factors that affect your productivity: the quality and speed of output, and the lifespan of your cutting tools. It’s usually possible to cut faster and deeper, but this will increase tool wear and may reduce accuracy.

What are the three factors that you need to consider for adjusting milling speed & feed?

- Production speed

- Tool life

- Quality and precision of cutting

You might need to use a more expensive cutting tool to make faster cuts, but this can increase your productivity, so it might be cost effective. Fast cuts might reduce precision, but if you are not working to precise tolerances this might not be important.

The milling feed and speed you use will depend on the balance between these factors, and you will learn to optimize speed, tool selection and throughput to make the best compromise that keeps your milling and drilling cost effective. This is quite easy to balance if you generally work on very similar materials and products.

What if I’m regularly changing between different milling & drilling tasks?

If every work session is different from the last one, and you don’t have long experience of cutter quality or workpiece material you have to think harder. If you have multiple machines, then you’ll also need to factor in the weight, rigidity and speed capabilities of your different machines to select the right one for the task. There’s a huge difference between a 10hp industrial machine and a 1hp benchtop machine.

If you are unsure of anything, then focus on spindle speed to get started. Spindle speed is the most important factor in establishing a balanced general milling speed and feed combination.

Cutter manufacturers often provide a recommendation for “cutting speed,” usually in feet per minute. This is not always useful – it’s normally measured as cutting speed at the edge of the tool, which depends on both spindle speed and cutter diameter.

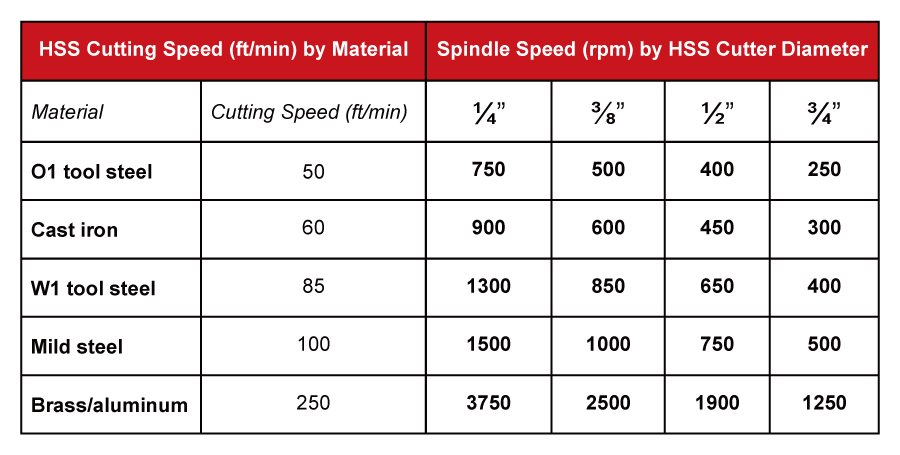

Standard spindle speeds for different materials and cutter sizes

A good starting point is to use a simple table of spindle speeds cross referenced by workpiece material and cutter sizes. Keep in mind that the most common problems are due to running small cutters too slowly or large cutters too fast.

This table is for HSS cutters. These are starting speeds, remember that cutter quality and sharpness vary and so does workpiece hardness even in the same materials. If you mill does not offer the recommended speeds then use the nearest speed possible. If you are using carbide cutters then you can run between two and four times faster than these speeds.

Which is the best direction for feeding the workpiece?

Now you have a good idea of how fast your spindle should be turning, you need to think about what direction to move the workpiece to cut it. You have two choices, to feed the workpiece against the rotation of the cutter or with the rotation of the cutter.

Feed direction should be against cutter rotation

Standard practice is to feed the workpiece against the direction of movement of the cutting edge. If you look at the picture above, the cutter will be rotating counterclockwise, and the feed should be from right to left. This is called conventional milling, or ‘up milling.’

Avoid climb milling: don’t feed with cutter rotation

You can also move the workpiece in the same direction as the cutting edge, this is called climb milling or ‘down milling.’ The problem with the workpiece going in the same direction as the cutter is that the cutter tries to pull the workpiece along in the same direction. This can move the workpiece and possibly damage the cutter, so you should avoid climb milling if possible.

How deep should you cut with your mill drill machine?

Once you have set up speed and feed rate correctly, you usually find depth of cut by careful experimentation. It’s best to start with very shallow cuts, as little as 0.02″, using a slow table feed rate. You can then build both cut depth and feed rate slowly. When the machine begins to vibrate, cut back the speed and feed rate slightly and you should be at the optimum depth and speed of cut.

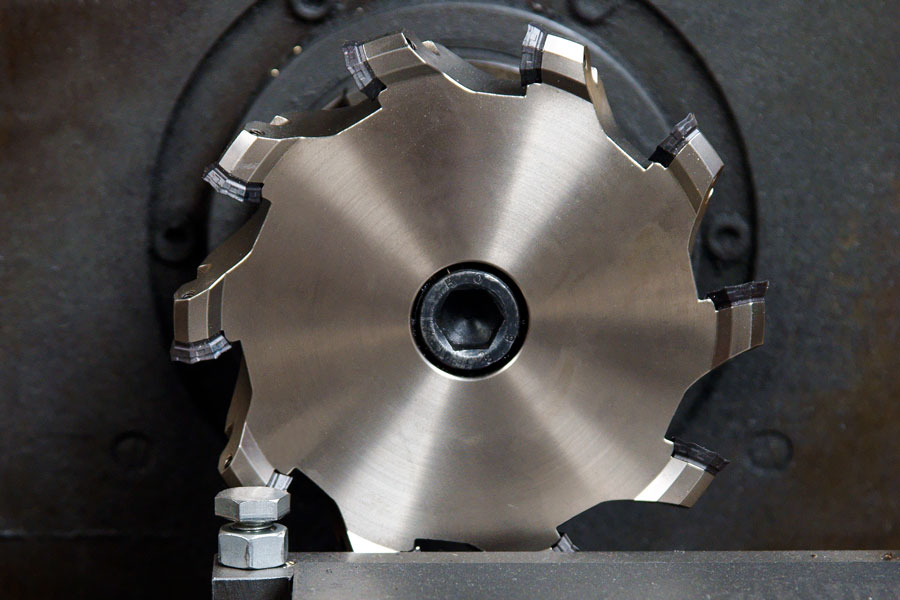

Rong Fu Mill Drill Machines For Fine Feed & Speed Adjustment

If you want to optimize your milling speed and feed, the quality of your mill drill will limit what you can do. As an experienced mill drill machine manufacturer, with excellent quality control, Rong Fu manufactures mill drill machines that help you achieve fine control of cutting speed and feed speed to get the best possible results.

Contact us to discover our range of mill drill machines based on excellence in design and manufacturing that guarantees accuracy and performance. We focus on precision and quality so you can achieve better productivity to higher standards in your milling and drilling projects.