How to index your mill drill machine to ensure repeatable high precision cutting performance

Indexing your mill drill machine is a necessary step in setting up your mill drill before you start milling and drilling. Indexing positions the cutting tool at a specific angle and location in relation to the workpiece. This enables you to cut symmetrical or repeating patterns on the workpiece, or to make exact cuts to remove material from the workpiece.

Table of Contents

When do you need to index your mill drill machine?

Indexing allows the operator to machine the workpiece at specific locations in a repeatable manner which produces parts with consistent dimensions and high quality surface finish. Precision is important to achieve accurate and tight tolerances on the final product. An example would be cutting a series of identical notches into a circular plate to make a toothed gear wheel.

Indexing also enables you to take full advantage of multi-fluted end mills and other specialized cutting tools which can remove material more efficiently and produce better quality parts. Indexing can also be used to create helical or spiral patterns on a workpiece, by rotating the workpiece or cutting tool to a series of angular positions while cutting.

Three reasons to index your mill drill machine correctly

- High quality surface finishes

- Precise and accurate cutting

- Enables use of specialized cutting tools

Indexing is an essential milling process that enables accurate and efficient machining of the workpiece. It can be done manually or digitally, depending on the machine. It is an important part of setting up your mill drill machine to ensure your cuts follow the desired path through the workpiece.

How do you index your mill drill machine?

A mill drill machine is indexed by adjusting the location of the spindle, which holds the cutting tool, in relation to the workpiece. This is done by rotating the spindle or the workpiece to a specific angular position, and then locking it in place using a clamp. In the image above you can see that the workpiece is mounted in a chuck that can be rotated to change the cutting position.

Manual indexing is done by turning the spindle or the workpiece by hand and visually aligning it with a reference mark. Digital indexing uses Digital Readout (DRO) systems to provide numerical readouts of the angular position.

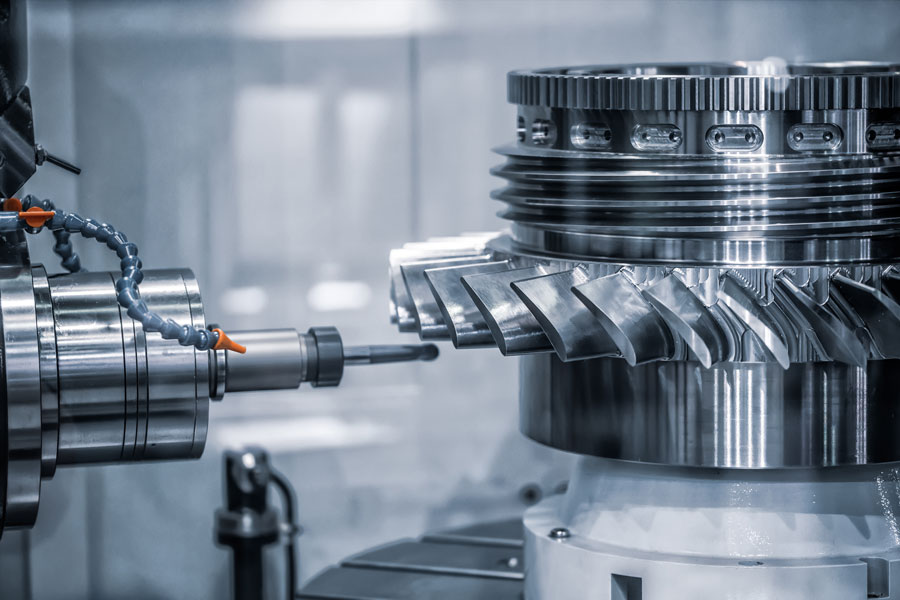

Some mill drill machines are equipped with an indexing head or rotary table that can be adjusted to specific angular positions to make indexing more precise. For the complex cutting operations shown in the image above, you can see that the workpiece is clamped to a rotary table that is turned in accurate increments to enable cutting each blade very precisely.

Indexing circular workpieces

When you index a circular workpiece you evenly divide the circumference into equally spaced divisions. This is how you get the positions correct to cut individual gear teeth, splines, mill grooves in reamers and taps, and spaced holes on a circle. An indexing head is used to do this manually.

What is an indexing head?

The indexing head is part of an indexing fixture, and contains an indexing mechanism used to control the rotation of the index head spindle to space or divide workpiece cutting positions accurately. A typical indexing mechanism might have a 40-tooth worm wheel on the index head spindle, a single-cut worm as a crank for turning the wormshaft, and an indexing plate.

Using the index to rotate the workpiece

With the workpiece clamped in the vise attached to the indexing fixture, if there are 40 teeth in the worm wheel, one turn of the index crank turns the index head spindle 1/40 of a turn, and turns the workpiece through 1/40 of a rotation.

What is an indexing plate?

The indexing plate is a round plate pre-drilled with a series of six or more circles of equally spaced holes. Most index heads come with a set of interchangeable plates with spacings that match standard spacing for most gears, splines and bolt heads. Indexing plates are used to rapidly align the index head spindle for common cutting positions, saving a lot of time!

Indexing in Degrees

You can also index a workpiece in degrees, either by dividing 360 degrees (a complete circle) by the number of turns of the indexing crank that make a full circle, or by having a circular table that has a reference scale in degrees around the edge and can be freely released, rotated, and clamped.

Rong Fu Mill Drill Machines Offer Extreme Cutting Precision

Rong Fu are a leading mill drill machine manufacturer, and pride ourselves on our quality control in manufacturing. This is why our mill drill machines will reward your attention to correct setting up and indexing by giving you excellent results.

Contact us to find out how our range of mill drill machines are built to the highest design standards to offer you the best performance with extreme accuracy. Our focus on precision and quality leaves you free to get the best results from your milling and drilling projects.