You might think the principles and uses of metal cutting bandsaws have stayed the same since they were first invented, but modern metal cutting bandsaws are more feature-rich than their primitive ancestors, even if they are designed to fulfill the same needs. Let’s see how customer preferences for metal cutting bandsaw features and technologies are making an impact in 2024.

Table of Contents

How are trends in metal cutting bandsaw technology changing?

The first thing that people tend to think about metal cutting bandsaw technology is that it is all about improving the quality, precision, speed, and safety of cutting, but there is a lot more to it than that. The relationship between technological improvements and metal cutting bandsaw design is a complex interaction between features that make bandsaws more effective, and features that make them more attractive to the user. In today’s market this includes optimizations for safety, efficiency and sustainability.

User experience is driving metal cutting bandsaw preferences

It’s no longer the case that you only need to be concerned with the needs of industrial and commercial workshops. Domestic ‘makers’ and small workshop customers are now expanding the market for affordable metal cutting bandsaws. These customers who are looking for the smaller capacity metal cutting bandsaws are also motivated by contemporary demands for feature-rich products with distinctive characteristics, and are looking for a range of options and designs to suit their personal preferences.

What is the impact of new and emerging customers on metal cutting bandsaw purchasing preferences?

For OEM brand retailers, it is important to consider a portfolio of technologies and features at different price points that will appeal across a wide range of potential customers. As metal cutting bandsaws have become less expensive in competitive markets, the potential for new customer types has increased. We should really ask ourselves which established technologies are being expected as standard features or options by new customers.

What metal cutting bandsaw technologies are now considered standard options?

- Bi-Metal & Carbide Blades

- Variable Speed Drives

- Simplified Blade Tensioning Systems

- Improved User Experience & Safety Features

- Sustainability & Energy Efficiency

Bi-metal and carbide blades offer longer blade life, faster cutting speeds, and the ability to handle a wider range of metals, including tougher alloys, which is a significant benefit for small workshops. Variable speed drives, whether geared or using pulleys, also offer benefits in adjusting cutting speeds for a wider range of materials when using a single machine, which is commonly the case for small workshops, where versatility is a significant benefit.

Blade tensioning can require some expertise and training to get the best results, so it should not be any surprise that there is an increase in options for tension meters and simple adjustment systems, especially for new and emerging customers with limited operational experience. It’s in the manufacturer’s interest to help the customer achieve cleaner cuts and improve efficiency in the simplest way possible.

User experience and safety features, like easily accessible control panels, safety cut-offs and effective guards have all become much more important as more people have become accustomed to using metal cutting bandsaws and they are not only found in commercial and industrial spaces. This is also a driver behind improved efficiency and sustainability, with more energy efficient motors.

Customer feedback tells you the metal cutting bandsaw features they want

In this digital age, some commercial and industrial customers are looking for improved automation and integration with their digital systems, but most workshop customers are more interested in reliability, safety, and ease of maintenance. Features like belt tension strain gauges and hydraulic vises are now commonly used on larger metal cutting bandsaws, and available as accessories across a wider range of models.

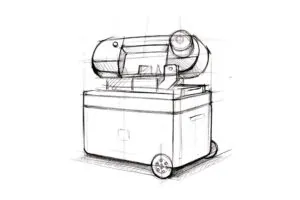

Semi-automatic bandsaws like the RF 300 pictured above, with a 12” / 300mm round and circular cutting capacity, are a popular option for commercial and industrial workshops. This is because the RF300 combines reliable, accurate operation with technology that makes it easier and less tiring to use, including modern features to ensure operator safety.

Features of the Rong Fu RF-300 Heavy Duty Semi Auto Bandsaw

- Semi-auto Cutting with Hydraulic Pump & Magnetic Switching

- Semi-auto Hydraulic Vise with 15 mm Travel

- Control Panel & Control Box located in Front for Easy Operation

- Heavy Duty Cast Iron Machine Base & Cast Iron Blade Wheels for Rigidity & Stability

- 4 Step Pulley Heavy Duty Gearbox

- Carbide Blade Guide & Bearings Increases Accuracy & Extends Blade Life

- Semi-automatic Cutting for High Productivity

- Magnetic Safety Power Off Switch

- Coolant System for Wet Cutting

- Wide Chip Tray with Filter Net for Easy Chip Collection & Cleaning

- One Way Swivel (optional with RF-300R)

- Single Column Feeding System for Stable & Precise Cutting (optional with RF-300A)

- Auto Feed System (optional with RF-300A)

A broad range of metal cutting bandsaws attracts customers to your brand

When you develop a partnership with Rong Fu for OEM metal cutting bandsaw manufacturing, you discover that our focus is not just on machines that cut metal but on optimizing metal cutting bandsaws for the efficiency, safety, and sustainability that attracts a wider range of customers.

All our bandsaws are built to exacting CE and global quality standards as part of our ISO certified Toyota Production System manufacturing process to ensure seamless compliance across any current or potential customer market.

Contact us to discover how we can help you build your metal cutting bandsaw brand performance by listening to the needs of your customers, and supplying you with the right range of bandsaws to match the expectations of emerging markets.