How do brands select the right OEM & ODM equipment providers to equip small and medium sized factories in 2025? As an OEM and ODM metal cutting bandsaw and mill drill manufacturer with long experience in responding to market demands, Rong Fu can work with you to identify the best features and options to include to make your equipment attractive to factory and workshop customers. \

Table of Contents

Do you need to choose between OEM & ODM partners for factory equipment manufacturing?

To make smart selections of features for machines that meet the needs of factory workshops, like the RF-1018R workshop metal cutting bandsaw shown above, you might think it’s a good idea to start by identifying which products are best suited for OEM or ODM manufacturing. In fact, it is usually best to work with the same company for both OEM and ODM manufacturing for several reasons.

Look for a partner with skills in both OEM & ODM equipment manufacturing

Your existing portfolio of designs may be OEM, but ODM is excellent for developing new markets without the additional risks and costs of making your own designs. This is why many brands look for a partner like Rong Fu, which is skilled in OEM and ODM for factory and workshop equipment manufacturing. When your OEM partner can also supply ODM products for your brand you gain the assurance of production efficiencies as well as consistent look and feel for your product branding.

What are 6 features of OEM & ODM manufacturing?

- OEM products are made to the design specifications of the client

- ODM products are designed by the manufacturer for the client

- Both OEM & ODM outsource manufacturing to a third party

- OEM & ODM remove the need for brands to maintain and manage their own factories

- ODM reduces the need to maintain an expert pool of engineering specialists

- Combined OEM & ODM partnerships improve supply chain efficiency and brand identity

Rong Fu OEM & ODM capabilities reduce the risk of entering new markets

Rong Fu combines the capacity and production line experience of longstanding OEM manufacturing with the skills and capabilities to produce high quality ODM equipment that creates a win-win relationship with our OEM and ODM customers. This is because we can satisfy their need for a stable supply chain for their well established OEM designs as well as assisting them with a reduced risk pathway to explore and develop new markets with ODM products.

What type of factory equipment is suited to OEM manufacturing?

OEM is used to make well established equipment designs from existing engineering drawings and plans. OEM depends on having your own in-house professional engineering design and marketing teams who are experts at deciding what features to include. You also need to have the technical capabilities to create new and innovative equipment designs without outside assistance.

The usual reasons for outsourcing manufacturing apply to both OEM and ODM, which include the benefits of not having to build and maintain your own equipment manufacturing facility and also the efficiency gains of working with an OEM / ODM partner who works at scale.

What are possible issues with OEM factory equipment specialists?

When you are looking for OEM factory equipment manufacturing, there are a few factors that you need to consider. A specialist manufacturer who focuses on OEM supply but does not have ODM capabilities will have many customers, all competing for production line capacity. Specialist OEM manufacturers do not need to employ design engineers and this can cause issues with quality control and oversight.

OEM factory and workshop equipment manufacturing should have flexible production systems to integrate new customers without disrupting the workflow. If you order a complex, sophisticated workshop machine like the RF-35 radial drill shown here, will your OEM specialist prioritise it over easier jobs?

What are 3 considerations for OEM factory equipment supply?

- What quality control systems does the OEM partner use?

- Can your intended OEM partner integrate orders into their workflow efficiently?

- How resilient is the OEM supply chain?

Check on the quality management system being used by your intended OEM factory equipment manufacturer. Your design may be excellent, but let down by quality control during manufacturing. This can also be a problem for supply chain management if an OEM partner does not have access to high quality materials or is in a location that is not well served by global shipping logistics.

When is ODM useful for workshop & factory equipment manufacturing?

You can use ODM to help your brand enter new markets without the risk that comes from in-house engineering design and prototyping. This makes ODM a sensible option for workshop and factory equipment manufacturing with an ODM partner who both has the capabilities and capacity to manufacture high quality equipment and also has the experience and expertise to identify and develop features and innovations that make your products more attractive to buyers from small and medium sized factories.

An experienced and technically skilled ODM factory equipment manufacturer will be able to build workshop machines to almost any specification, and will also be able to offer design innovations, upgrades, and a portfolio of accessory options. Longstanding ODM manufacturers have the market experience to be able to advise on what is likely to be popular for a specific market segment.

When technology changes and new products and features are introduced, working with an ODM is much easier than trying to maintain an in-house design and engineering team that has to be constantly innovating. R&D can be very time consuming and expensive, whereas you are likely to find that an ODM manufacturer has already designed the product you want with the features you need and all you need to do is to add the branding.

Rong Fu can readily integrate digital readouts, hydraulic clamping systems, touchscreen interfaces, DC motors, and other attractive features into ODM products for your brand without you having to maintain the expertise and engineering staff to develop these in your own R&D program.

Rong Fu OEM & ODM for metal cutting bandsaws & mill drills

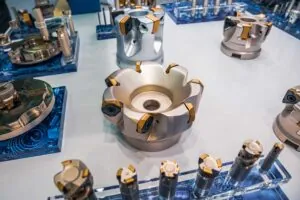

Rong Fu ODM metal cutting bandsaws and mill drill machines are based on more than 50 years of experience and innovation. We have built award winning designs for ODM metal cutting bandsaws and mill drills alongside production of a wide range of globally recognized OEM brands. Our RF-500 mill drill, pictured above, is a typical example of the fully-featured, factory-ready ODM equipment we offer.

The Rong Fu factory in Taiwan uses the Toyota Production System methodology to ensure quality and maintain efficient parallel workflow for all our OEM and ODM customers, enabling us to give you accurate delivery schedules to meet your needs. Taiwan is a shipping nexus for high quality materials and supply chain stability as well as being a low tariff country in 2025 for most global partners.

What are 7 reasons to partner with Rong Fu as your OEM & ODM manufacturer?

- Prior experience and existing skills, tooling and workforce capabilities make it highly cost effective to work with us to develop ODM metal cutting bandsaws & mill drills.

- Our production line is designed for both OEM & ODM flexibility to ensure our customers receive their equipment on time and according to schedule.

- We have the capabilities to manufacture all types of OEM equipment as well as the ODM engineering skills to ensure quality control and efficient production.

- You can significantly reduce research and development costs and retain profits by using our ODM services.

- You can get your new Rong Fu ODM product to the market much more quickly than your competitors.

- Rapid product development increases adaptability to respond to market changes and changing consumer preferences, like the demand for touch screen controls, DC motors and ergonomic styling.

- Our ODM engineers have considerable background experience and expertise that can be used for rapid customization of products to meet new, emerging & specific requirements.

Our expertise in ODM bandsaws and mill drills creates an opportunity for you to expand your portfolio of machines for small and medium sized factories without incurring significant development costs with uncertain returns. Contact us to discuss how partnering with Rong Fu gives you access to high quality ISO certified and globally compliant ODM equipment and high quality OEM options for your brand.