The Rong Fu RF-712N: a case study in metal cutting bandsaw evolution

We’re going to take a look at the features that we have introduced to the Rong Fu RF-712N that have driven its evolution into a better metal cutting bandsaw through Rong Fu design integration that meets the needs of both OEM manufacturers and their customers. The original design dates back to 2004, and has been through many iterations and improvements, most recently in response to feedback we collected from customers and manufacturers between 2021 and 2024.

Table of Contents

The evolution of Rong Fu OEM metal cutting bandsaws is the result of integrated design, technology and user experience. The result is award winning, superior products that satisfy the evolving requirements of our OEM clients and their customers for better OEM metal cutting bandsaws.

How does swivel vise design improve metal cutting bandsaw user experience?

The redesigned swivel vise responds to customer feedback asking for a rapid, secure method of adjusting the vise without specialized tools. The solution integrates efficient, well tested, engineering design with customer preference for ease of use and rapid adjustment. Using standard 19mm bolts to clamp and release the vise improves the metal cutting bandsaw user experience.

Why does metal cutting bandsaw manufacturing need integrated design?

OEM metal cutting bandsaw evolution can be slow, with many manufacturers using old technologies and machine designs even when improvements are possible. This makes it hard to attract new customers who expect a better user experience and are not focused on traditional technology. Integrated design enables OEM metal cutting bandsaw manufacturers to combine traditional technologies with improved user experience features and emerging technologies. This is attractive to both existing and new customers.

Why did we simplify the axial locking mechanism for metal cutting bandsaws?

Feedback from user experience surveys led us to change from the use of locking screws to standard hex head nuts for both the swivel vise and the axial locking nut of the RF 712-N metal cutting bandsaw. This is an example of integrated design where complexity is reduced by implementing simpler systems that are preferred by customers for their ease of use. We include a 19mm crescent wrench in the machine tools and accessories box, and no special tools are required.

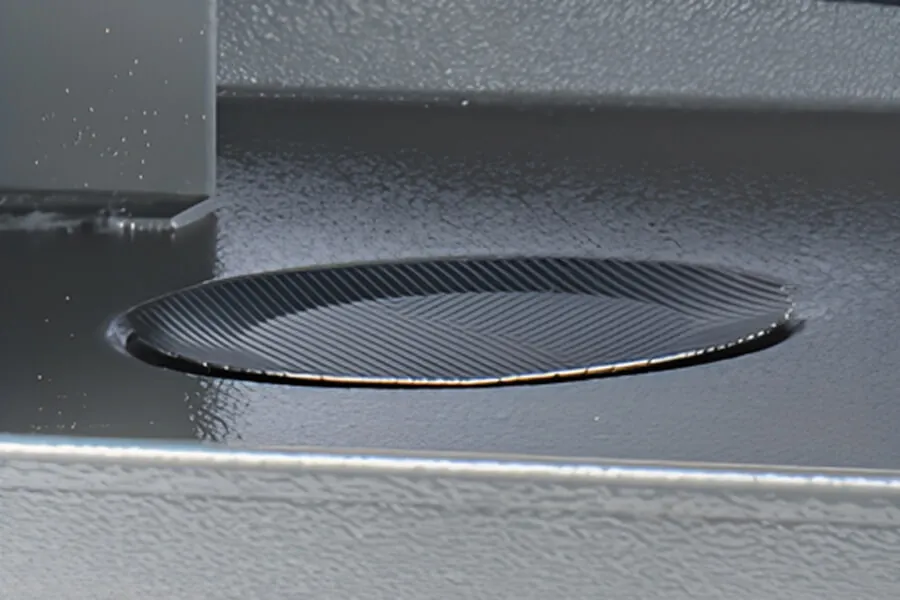

Integrated design improvement of metal cutting bandsaw sump filters

Integrated design helps you find details that contribute to the continuous improvement process for OEM metal cutting bandsaws. Our previous design had a thin, recessed coolant fluid coarse filter mesh screen built into the sump under the bandsaw. You can see this in the picture above. This design tended to trap metal chips and was sometimes damaged when removed for cleaning because it was a snap-fit that had to be gently pried free from the sump.

Our improved metal cutting bandsaw filter design is stronger & easier to maintain

The new design features a domed cover made of thicker metal. This is easier to keep clear during operation, stronger, and also simple to remove without risk of damage or distortion to the filter mesh. The addition of a central screw makes the removal process more obvious and eliminates the risk of damage that can occur when prying a mesh filter screen out of the sump tray.

Changes to coolant system design extend machine life with no additional cost

Maintaining clean, steady coolant flow is critically important to keep your metal cutting bandsaw operating at maximum efficiency. It is also important to ensure that the flow of coolant effectively clears chips and swarf from the cutting edge. This makes coolant filtration and removal of chips and swarf very important. For the best user experience OEM metal cutting bandsaw manufacturers need to have coolant systems that are effective but also easy to maintain.

A secondary coarse filter screen stops metal chips from entering the pump

In addition to restyling the sump mesh screen for the new RF-712N metal cutting bandsaw, we added a secondary coarse filter to the coolant pump, which you can see in the comparison images above. The previous design did not have a coarse filter, but this could enable metal chips that entered the coolant tank to enter the pump itself, causing wear and potentially blockages as well as returning chips to the cutting edge of the bandsaw.

The Rong Fu RF-712N demonstrates evolution driven by customer insights

- Integrated customer feedback and user experience collected from 2021-2024

- Holistic approach to design improvements

- Integrated design helps to keep pace with operational needs and market demands

- Comprehensive updates improve competitiveness and market appeal

Effective metal cutting bandsaw improvements at no extra cost

We worked with our local pump manufacturer to improve the design and add a coarse filter without increasing the cost per unit, and while maintaining our production efficiency due to our excellent relationship with our process-critical manufacturing and supply chain partners, who are all based in Taiwan.

Discover how Rong Fu keeps you ahead of the competition

Rong Fu has been manufacturing metal cutting bandsaws for more than 40 years. Our ODM metal cutting bandsaws have won awards, and we are known for our practical, effective, approach to customer centered innovation. Contact us to discover how partnering with Rong Fu will give you high quality ISO certified, globally compliant metal cutting bandsaws that keep you ahead of the competition. Our Toyota Production System ensures flexibility and rapid response times regardless of the volume or variety of your needs.