Our extensive product line of metal cutting band saw machines includes high speed and variable blade speed manual and semi-automatic bandsaws in portable, bench top and floor standing formats.

We have a wide range of metal cutting band saws and metalworking machinery. Our metal cutting band saw range is grouped by machine size & cutting capacity. This makes it easy for you to quickly find the model that suits your needs.

We design and manufacture supply metal cutting band saw machines with a variety of features and options to suit different customer requirements:

We work closely with our customers to identify the most significant and useful features they require.

The excellent reliability and quality of our metal cutting band saws derives from 40 years of expertise in matching products to the needs of all types of customers.

We are a fully vertically integrated enterprise. We maintain control over all aspects of the design, manufacturing and quality control process. We are the OEM metalworking bandsaw manufacturer of choice for our customers.

We are focused on the quality of each and every unit we produce for our global customers. All of our production and assembly is completed in house to maintain total quality control over the entire process.

Our control of the process from design to delivery allows us to rapidly respond to customers varies business requirements and customization needs. We also have the in house expertise to deliver the excellence of after sales service that our customers demand.

We enforce rigorous quality control and testing procedures and maintain ISO9001 registration for all of our manufacturing processes. Our metal cutting band saws exceed the requirements of global markets, including CE certification for Europe.

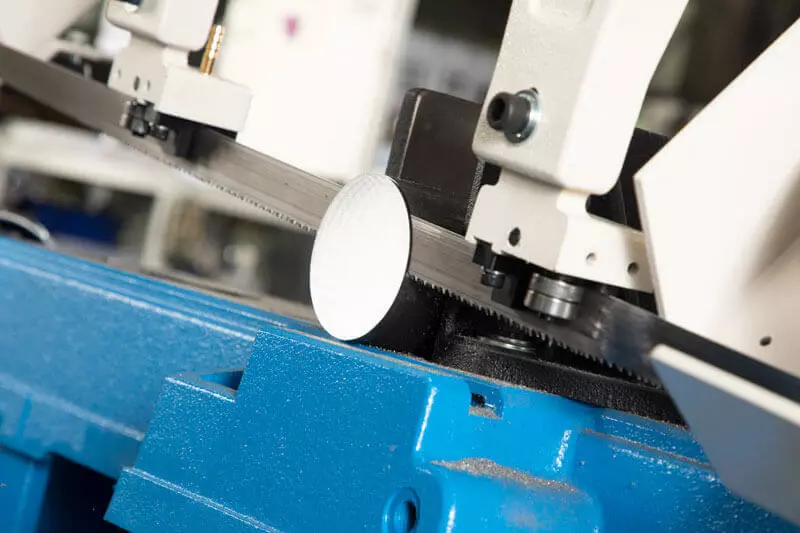

All of our products are tested and calibrated by our expert staff before shipping. Our quality control team carry out inline inspections and test cuts to ensure all products are within tolerance and the test documentation and samples are packaged with the bandsaw when it is dispatched.

Gear driven metal cutting bandsaws are an efficient, durable option for high torque, heavy duty applications in modern industries. Gear driven bandsaws are especially useful

The Red Dot award is the world’s most prestigious design award for innovation and technology. Rong Fu is proud to announce that we have won

Mill drill machines are easier to use in 2025 because of innovations in touch screen control panels, displays and interfaces. Rong Fu enhances user experience with mill drill designs that meet emerging customer expectations.

| Service | Cookies | Description |

|---|---|---|

| Google Analytics | _gat_gtag, _ga, _gid | Used to distinguish users and sessions for web statistics purposes. |

| Facebook Pixel | fr | Helps in determining efficiency of our advertising policy. |

| Youtube | APISID, CONSENT, HSID, LOGIN_INFO, PREF, SAPISID, SIDCC, SID, SSID, ST, VISITOR_INFO1_LIVE, YSC | Stores various information regarding user's preferences. |

| Service | Cookies | Description | |

|---|---|---|---|

| Google Analytics | _gat_gtag, _ga, _gid | Used to distinguish users and sessions for web statistics purposes. | |

| Facebook Pixel | fr | Helps in determining efficiency of our advertising policy. | |

| Youtube | APISID, CONSENT, HSID, LOGIN_INFO, PREF, SAPISID, SIDCC, SID, SSID, ST, VISITOR_INFO1_LIVE, YSC | Stores various information regarding user's preferences. |