With our over 50 years of expertise as an OEM manufacturer we are committed to delivering cutting-edge band saw technology tailored to meet your unique application requirements.

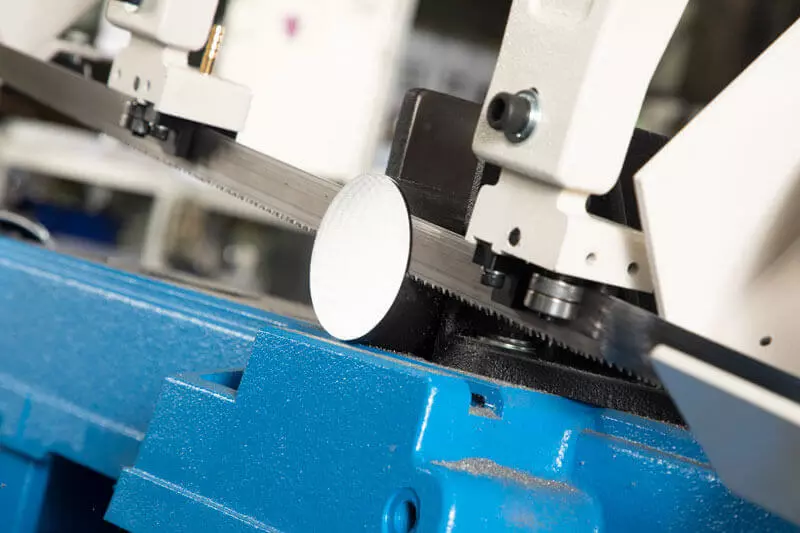

We offer an extensive range of steel cutting band saw machine and metalworking sawing machinery. We have grouped our metal band saw range by machine size & cutting capacity to help you quickly find the model that suits your needs.

We can supply metal cutting band saw machines with a variety of features and options depending on the exact requirement:

We work closely with our customers to identify the most significant and useful features they require.

The high quality and reliability of our metal-cutting bandsaws comes from 50 years of experience in matching products to the needs of all types of customer.

We are a vertically integrated company, and control all parts of the design, manufacturing and quality control process without outsourcing. This is why we are an OEM metalworking bandsaw manufacturer of choice for our customers.

Our commitment to quality is enabled by our management of the whole process of equipment development, manufacture and testing. Unlike some bandsaw suppliers we do not outsource our production process.

This enables us to respond quickly to customer requests for specific features and products. In-house manufacturing ensures that we have expertise on hand to respond to service and use questions rapidly and expertly, saving time for our customers.

We practice strict quality control and testing procedures and maintain ISO9001 registration for our processes. Our metal cutting bandsaws meet or exceed the requirements of global markets, including CE certification in Europe.

All equipment is rigorously tested and calibrated by our expert staff before shipping. The test cuts that our quality control team carry out are measured to ensure they are within tolerance and the test documentation and samples are packaged with the bandsaw when it is dispatched.

Sometimes what look like very small changes and adjustments can make a big difference for our OEM metal cutting bandsaw customers, and nothing is worse

The Rong Fu RF-712N: a case study in metal cutting bandsaw evolution We’re going to take a look at the features that we have introduced

Vertical integration is an effective method of maintaining control over supply chain, production and scheduling for OEM mill drill manufacturing. Rong Fu uses vertical integration

For over 50 years, Rong Fu has been a leading OEM manufacturer of high-quality metal cutting band saws and mill drill machines. We supply globally recognized brands with reliable, efficient metalworking machinery, made in Taiwan to Toyota Production System quality standards.

Our horizontal band saw machines offer extensive customization including blade speed adjustments, cutting capacity modifications, and specialized clamping systems tailored to your material specifications. We can configure band saws to handle varying workpiece dimensions, hardness levels, and production volume requirements with custom blade guides and coolant and control systems.

Standard semi-automatic band saw models typically have a lead time of 45-60 days for bulk orders, while customized configurations may require longer depending on specification complexity. We can expedite orders for established clients with advance planning.

All our band saw machines are manufactured under ISO 9001 certified processes and meet CE safety directives for export markets. We provide complete documentation including material certifications, testing reports, and compliance certificates with each shipment to facilitate your quality assurance procedures.

Our horizontal band saw line accommodates cutting capacities from 200mm to 500mm for round materials and up to 800mm for rectangular sections. Each model features robust construction with precision guide systems to maintain cutting accuracy within ±0.5mm tolerance for structural steel and similar ferrous materials.

We maintain a comprehensive spare parts inventory with global shipping capabilities and provide 24-month warranty coverage on all band saw machines. Technical support includes remote diagnostics, video consultation, and on-site service options, with critical wear components like blade guides and bearings available for immediate dispatch.

Our semi-automatic band saw models feature standardized control interfaces compatible with PLC systems and can integrate with material handling equipment through programmable I/O ports. We provide technical specifications and support for system integration, including custom programming for synchronized operation with conveyor systems and automated loading mechanisms.

Our horizontal band saw machines offer variable blade speed control ranging from 20-120 m/min through inverter-driven systems, allowing optimization for different material types and hardness levels. Advanced models include digital speed displays, programmable cutting parameters, and automatic feed rate adjustment to maximize blade life and cutting efficiency.

Each semi-automatic band saw undergoes a rigorous multi-stage inspection process including component testing, assembly verification, and full load testing before shipment. We implement statistical process control with documented traceability, conduct random sampling inspections per AQL standards, and provide individual machine test reports with performance data.

| Service | Cookies | Description |

|---|---|---|

| Google Analytics | _gat_gtag, _ga, _gid | Used to distinguish users and sessions for web statistics purposes. |

| Facebook Pixel | fr | Helps in determining efficiency of our advertising policy. |

| Youtube | APISID, CONSENT, HSID, LOGIN_INFO, PREF, SAPISID, SIDCC, SID, SSID, ST, VISITOR_INFO1_LIVE, YSC | Stores various information regarding user's preferences. |

| Service | Cookies | Description | |

|---|---|---|---|

| Google Analytics | _gat_gtag, _ga, _gid | Used to distinguish users and sessions for web statistics purposes. | |

| Facebook Pixel | fr | Helps in determining efficiency of our advertising policy. | |

| Youtube | APISID, CONSENT, HSID, LOGIN_INFO, PREF, SAPISID, SIDCC, SID, SSID, ST, VISITOR_INFO1_LIVE, YSC | Stores various information regarding user's preferences. |