A step by step guide to safe use of your metal band saw

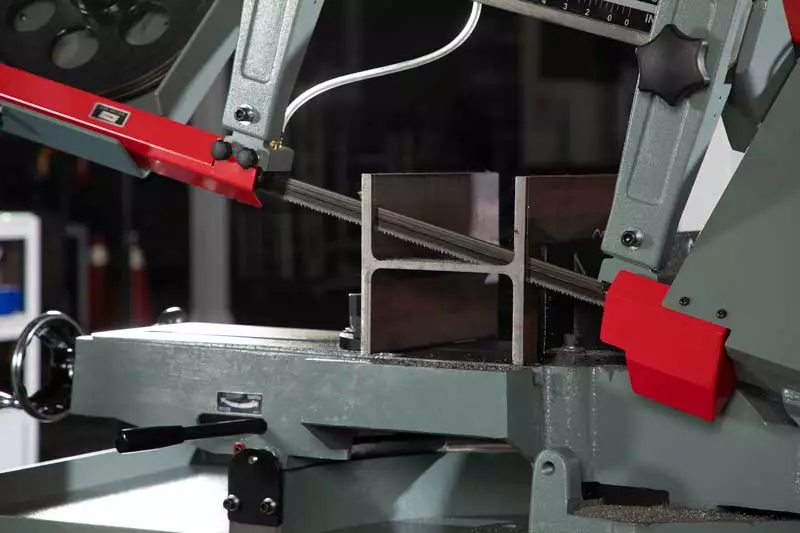

Metal band saws, like the Rong Fu RF 250S pictured above, are powerful machines with many moving parts. High quality metal cutting bandsaws have guards and covers, but it is the operator’s responsibility to ensure that you operate your metal cutting band saw safely.

Table of Contents

Metal Band Saw Health & Safety Considerations

We’ve put together this checklist of the four things you should consider to use your metal cutting band saw safely. If you are an experienced operator, it can help to refresh your knowledge and think about your working practices. Long experience with machines can sometimes make us less careful than we should be.

- Safety Equipment

- Safe Operating Procedures

- Correct Clamping

- Safe Operation

Safety Equipment

- Wear Safety Glasses

- Do Not Wear Loose Clothing Or Jewelry

- Ensure Safety Covers Are Secure

- Support Heavy Or Long Stock

- Use An Electrical Isolator

Wear safety glasses when operating the metal band saw to protect your eyes from chips. Never wear loose clothing, or jewelry, this can get caught in moving parts and cause serious injury. Keep the blade cover and equipment guards in place at all times, and use a support when cutting heavy or long stock so it doesn’t hang down.

Safe Operating Procedures

- Clamp metal securely before sawing

- Adjust the arm guide rollers correctly

- Check coolant is flowing over the stock

Secure clamping and ensuring the guide rollers are as close as possible to the stock are essential for minimizing vibration and prolonging blade life. Ensure coolant flow is directed over the stock before cutting with your metal cutting bandsaw.

- Switch off and isolate the bandsaw for servicing or adjustments

- Never leave the saw unattended while in operation

- Clean up coolant water and metal shards

Always isolate the electrical power when servicing the saw or replacing blades, and never make adjustments while the metal cutting bandsaw is operating. Do not leave the saw operating unattended, and keep the floor free of coolant water and metal shards to reduce the risk of slipping.

Correct Clamping for your Metal Band Saw

- Place stock in the vise and clamp firmly

- Cut round, flat & angle stock separately

- Use a support for long & heavy stock

Firm and secure clamping is absolutely essential. Do not attempt to mix stock of different shapes in the vise, but clamp round, flat, and angle stock separately. Always use a support for long and heavy stock.

- Stand flat stock on edge and clamp together

- Clamp the widest side of rectangular stock towards the blade

- Clamp angle iron with legs downwards

If cutting a stack of flat metal, set the stack on edge and clamp it together tightly in the vise. Rectangular stock should be clamped with the widest side towards the blade, and angle airon should be clamped with the open ‘legs’ downwards in the vice.

Safe Operation

- ower the blade slowly until it makes contact with stock\

- Maintain proper feed pressure

- Do not increase pressure if the saw cuts slowly or binds

After starting the metal cutting bandsaw, lower the blade head slowly until the blade makes contact with stock. This will prevent damaging the blade teeth. Keep proper feed pressure on the hydraulic feed control. If the saw cuts too slowly or binds, replace the blade – do not apply pressure to the blade head.

- Supports for long stock should not be higher than the vise

- Remove unused stock from the vise after cutting

- Be aware of your surroundings

Supports for long or heavy stock should be no higher than the vise to prevent pinching the blade as it cuts through the stock. Remove unused stock from the saw to prevent others from walking into it. Maintain awareness of your surroundings so you identify potential hazards before they cause problems.

Safety Is A Quality Issue

When looking for a metal cutting band saw, the quality of the saw is important for safe operation. There are limits to how safe you can be if the saw has faults in construction, or does not come equipped with proper safety equipment.

At Rong Fu we pride ourselves on our attention to quality control in manufacturing and our long experience in designing excellent bandsaws, which include many safety features. Contact us to find out more.