There are several innovations and upgrades that can make OEM mill drill machines easier and safer for customers to use in 2025. Rong Fu improves the operational convenience of mill drill machines with intuitive controls, displays that improve user experience and options for digital touch screen control panels to enhance the user interface.

Table of Contents

What is the Operational Convenience of a Mill Drill Machine?

Mill drill machines were developed to improve the operational convenience and streamline the efficiency of multiple metal machining operations in one convenient tool. The mill drill machine is itself a tool of convenience, combining milling and drilling capabilities, in freestanding or compact benchtop format. In 2025, user interfaces and the user experience are important design features for improving mill drills.

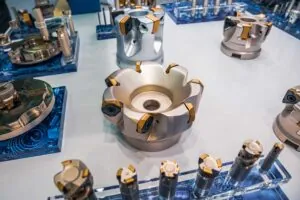

Milling and drilling are logical features to combine in a single machine because both machines rely on a spindle mounted cutting tool, the difference is that drills are only designed to cut along the axis of the tool, whereas milling machines can both cut across the faces of the workpiece and drill holes. Contemporary control systems and readouts enhance the existing physical convenience of the mill drill machine.

How many metal cutting machines can be combined in one package?

There are limits to how many machines can be combined in one package! Why not add a lathe to create a 3-in-1 mill drill lathe? Experienced machinists tend not to buy 3-in-1 machines for several reasons. Setup time and task switching takes longer and it is much harder to get good results than with dedicated mill drill machines and lathes.

3-in-1 mill drill lathes offer low precision machining in a small footprint, so are targeted at hobby machinists with space limitations. As this comment thread suggests, if you have limited space you would be better off with a compact Rong Fu RF-45 mill drill and a separate lathe rather than trying to combine all functions in a cheap combination mill/lathe and losing precision and efficiency.

A mill drill requires improvements to the rigidity, tool holding and bearing design of the spindle compared to a drilling machine and a table that can be moved laterally under control with very secure and precise workpiece clamping.

When measuring operational convenience, or ease of use, of a metal cutting machine, we need to consider several factors. The logical combination of tasks for efficiency is one of the most important – and is why high quality mill drill machines are generally regarded to be a good combination.

What features make mill drill machines easier to use?

Convenience features that make mill drill machines easier to use can be split into several categories. Operational convenience is enhanced by both improving the user experience and user interface of modern mill drill machines. User experience is improved by features and options that make the mill drill machine physically less demanding for the operator to use.

- Powered downfeed

- Powered table feed

- Easily adjustable stands and guides

- Integrated coolant & lubrication systems

- Working lights

- Digital readout options

- Touch panel controls

- Safety interlocks

Powered downfeeds and powered table feeds are a good example of a convenience feature that increases efficiency and safety by reducing operator fatigue. This enables rapid setup and accurate duplication of repetitive machining tasks, and also helps to maintain precision when multiple milling or drilling operations are required.

What are 5 mill drill machine ease of use features for 2025?

- Simple, intuitive controls

- Informative, clear displays

- Touch screen functionality

- DC motors with PWM controllers

- Automatic safety sensors

Integrated coolant and lubrication systems with easily accessible reservoirs and filters are another feature that improves the operator experience and has the additional benefit of improving milling precision and drill bit and milling cutter life by reducing wear and avoiding common overheating problems.

Efficient, bright working lights also reduce operator fatigue, increase accuracy and add another safety measure as they reduce the likelihood of an operator moving too close to the machine to ‘get a better look’ at the work in progress when there is poor ambient lighting.

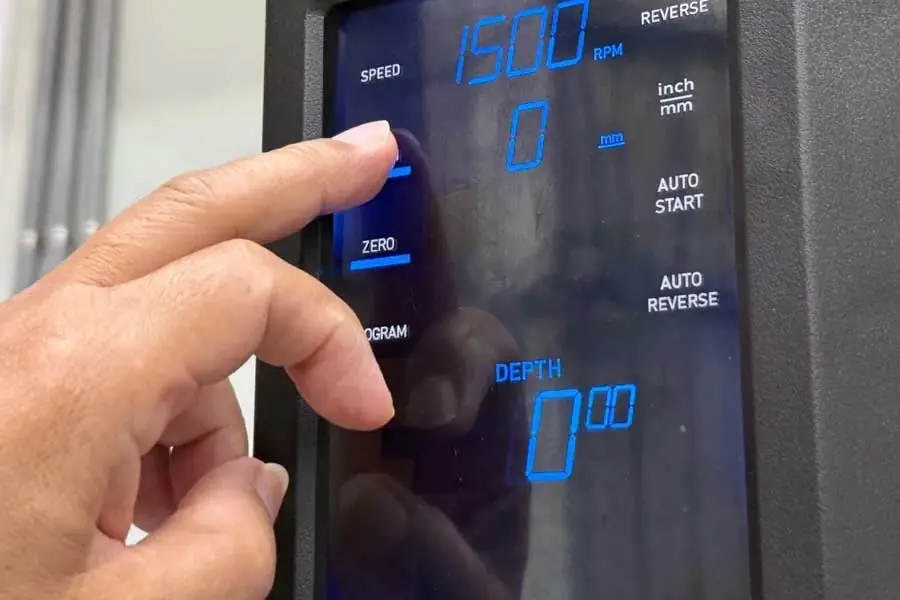

Clear, digital readouts, and clearly identifiable controls with appropriate icons, symbols or diagrams are a must-have user interface for mill drill machines in 2025. The 3-axis digital position readout (DRO) and touch screen shown above for the Rong Fu RF-45 mill drill offer typical examples of modern control panels. These offer immediate at-a-glance verification for the operator of cutting progress and can even offer warning in advance of potential issues.

Why are touch panels for mill drill machine controls becoming more popular?

Touch panels for mill drill machine controls are becoming increasingly popular as machines become cleaner and better enclosed and guarded. This reduces the likelihood of oil, grease, coolant, swarf and chips being transferred to the operator. Not only does this improve health, safety and comfort for the mill drill operator, it also makes touch screens a practical option for controlling modern mill drill machines.

Touch sensitive screens and display panels are a potential game-changer for mill drill machines, as they also provide the opportunity for in-depth programming and customization of sensor and machine status data to match a wide range of customer requirements using the same baseline machine with different programming settings.

What if I can’t use a touch screen for my workshop machinery?

OEM mill drills and metal cutting bandsaws are among the workshop machines that use digital and electronic controls for a better user experience. However, touch screens are not practical in all settings. For heavy industry where full PPE protection is expected, and in environments where moisture, oil, coolant and machining chips are almost inevitable, a more rugged solution is required.

The controls of the RF-500 semi-auto metal cutting band saw shown above are an excellent example of how to maintain a contemporary high-quality user experience when you need to use dials, toggles, joysticks and microswitches as a functional alternative to touch sensitive screens. This example is ergonomically designed with universal diagrammatic labelling to make it as clear and intuitive as possible.

Integrated sensors improve cutting efficiency as well as safety

Modern sensors can provide more accurate and finely tuned data and combined with modern servo, hydraulic and PWM DC motor controls are able to translate these into precision movements and procedures that can be adjusted in user-friendly increments. This is a significant improvement upon expecting customers to be happy with “one-size-fits-all” controls and features.

Sensor technology enables safe auto-start and auto-stop of the mill drill motor as the bit is lowered or raised. Auto-reverse screw tapping is easy to set up with touch-screen digital operator programming, and precision speed control for optimized cutting using DC motors with PWM controllers is easy to program into a modern control unit alongside sensor lockouts for everything from open safety screens to verifying the spindle is obstruction free before operation.

Rong Fu: Operator Convenience for Mill Drill Machines in 2025

Customers are now expecting more user-friendly features in mill drill machine technology, with controls and settings clearly visible and easily adjustable. To meet these requirements for operator convenience in 2025 to satisfy new and emerging customers it is necessary to adapt and update product lines. We have over 50 years of experience serving our global customers and responding to change, so with Rong Fu it’s surprisingly easy to implement change.

Rong Fu is ready to supply OEM mill drill machines in a range that meets the requirements of all types of customers, and with full-featured accessories that include stands, tapping switches, chuck and table options, lubrication and feed controls to make your mill drill machines stand out for ease of use and user-friendly operation. Contact us to learn more!