Vertical integration is an effective method of maintaining control over supply chain, production and scheduling for OEM mill drill manufacturing. Rong Fu uses vertical integration to improve supply chain stability, shorten lead times, and ensure flexible shipments to our global and regional OEM brands regardless of the scale and scope of their market. Our parallel manufacturing lines follow Toyota Production System principles to deliver unparalleled mill drill manufacturing efficiency and quality control.

Table of Contents

Vertical integration eliminates delays in critical components for mill drill manufacturing

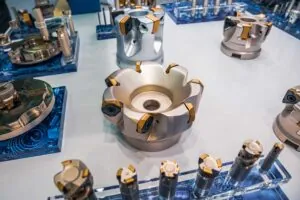

There are many potentially long lead time critical components that are used in mill drill manufacturing, including castings, gearboxes and control systems. Outsourcing these components can cause supply chain disruption due to lack of control over manufacturing and quality processes. Vertical integration is an effective method of eliminating delays caused by potentially unreliable component supply chains.

Our in-house engineering team and manufacturing capabilities enable us to design and build innovative mill drill machines without outsourcing. This aspect of our vertical integration reduces risk from reliance on third party contracting and maintains consistent supply high quality parts and components for our mill drill manufacturing services.

Rong Fu uses predictive inventory control to ensure we always have sufficient inventory of high risk components on hand to ensure rapid turnaround for all of our standard mill drill models as well as historic OEM models with aftermarket parts and support demands. This means that our regional and global partners do not need to worry about customer complaints arising from inability to obtain spare parts for current or historic mill drill machines.

Vertically integrated mill drill manufacturing increases quality and shortens lead times

Our vertical integration of planning, production, and supply is a core feature of our use of the Toyota Production System (TPS) for our mill drill manufacturing lines. We apply the exacting quality standards of the TPS to ensure shorter lead times and stable supply chains for our OEM mill drill customers.

What are 4 benefits of vertically integrated mill drill manufacturing?

- Shorter lead times

- Improved quality control

- Stable supply chains

- Flexible shipments

Rong Fu maintains sufficient material stock holding and specialist supply chain guarantees to meet any capacity requirements for flexible shipments. Because of this, we are able to switch production lines to parallel manufacturing of different mill drill models on demand and deliver mixed orders with short lead times to regional and international OEM mill drill brand partners.

How does vertical integration of mill drill manufacturing increase supply chain stability?

Supply chain stability is essential to reduce business risk, both for our own internal mill drill manufacturing and also for the supply of OEM mill drill machines to the Asia Pacific region and internationally. Research demonstrates that vertical integration reduces financial and business risks partly because of how it enables better control of supply chains. Rong Fu uses vertical integration of all mission critical mill drill manufacturing and supply chain stages to maximize supply chain stability.

By maintaining close monitoring and control of vertically integrated mill drill manufacturing at our factory site in Taiwan we are able to reduce cost volatility from raw material supply chains as well as minimizing reputational risks that can arise from failure to deliver customer orders, especially during peak sales periods. Better control of supply chain relationships between manufacturers, distributors and retailers improves business performance because vertical integration facilitates effective strategic partnerships.

How are lead times and supply chains affected by technological innovation in mill drill manufacturing?

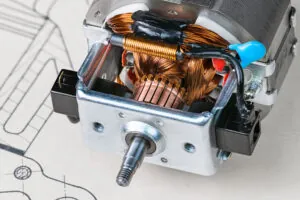

Technological innovation in mill drill manufacturing without experienced, dedicated process and production oversight increases lead times and hold-ups in supply chains.This is because increased complexity and sophistication in mill drill design increases the number of potential quality issues and likelihood of supply chain failures for critical components in manufacturing systems that rely on outsourcing.

Demands by customers for a better user experience has a significant impact on mill drill manufacturing. This is an area of technological innovation in OEM mill drill manufacturing that is driving the market today as end users expect smart features including touch screen interfaces to be among the options available for OEM mill drill machines. Vertical integration reduces the risk of adopting new technologies that customers want.

How can vertical integration help your OEM mill drill supply chain?

Rong Fu has been manufacturing OEM metal cutting bandsaws and mill drills for more than fifty years, and our extensive range of mill drill machines has been built from this long experience. The answer to how vertical integration can help your OEM mill drill supply chain is to work with us, and gain the benefits of our vertically integrated business, supply chain, and manufacturing experience.

What certifications does Rong Fu maintain?

- ISO 9001:2015 Certified SGS TW08/00322 for mill drills & bandsaw machine manufacturing

- ISO 9001 Certification for Quality Assurance

- ETL Listed certifications from Intertek, control number 5032069, for US & Canada

- CE certification for our products for European markets

- Taiwan Ministry of Labor Certificate number TD110048: TS machinery occupational safety.

We have mentioned our dedication to Toyota Production System principles, which enables us to offer flexible shipments and shorter lead times. We also maintain quality management, safety, and product certifications for all key markets, giving our OEM brand partners additional peace of mind. Contact us and discover how you can benefit from working in partnership with us to supply your OEM mill drill machines with the assurance of stable supply chains and reduced business risks.