Manufacturers of mill drills and metal cutting bandsaws are offering digital control options for their OEM and ODM products. This industry trend is driven by customer demand for interfaces that are familiar to them across multiple technology platforms from smart phones to car navigation systems. Let’s see how R&D in metal cutting workshop machinery manufacturing is responding to this challenge.

Table of Contents

What is driving technological innovation in mill drill & metal cutting bandsaw manufacturing?

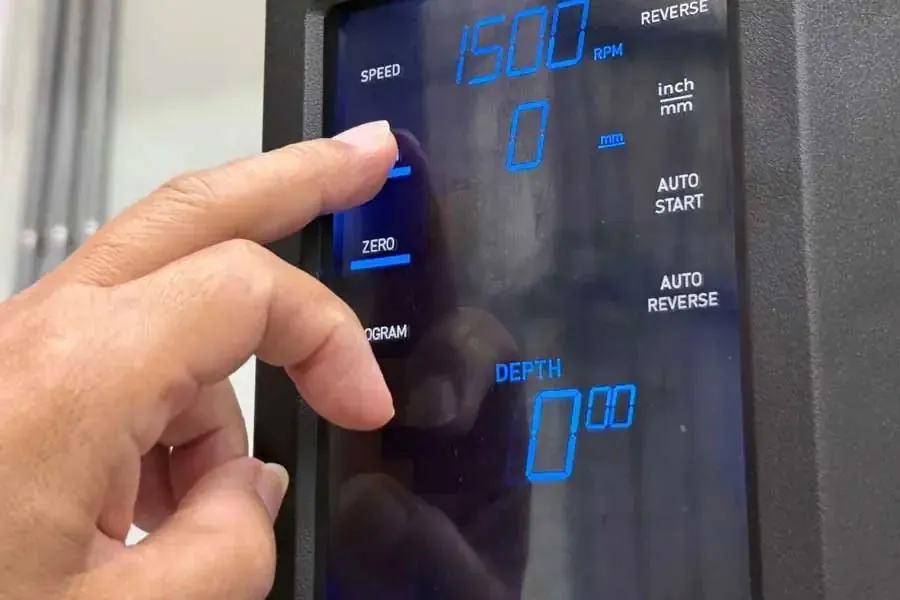

Technological innovations in OEM mill drill manufacturing are driving the adoption of features that improve ease of use. This includes digital controls, digital panels and touch screens for digital control of workshop machine parameters. This is all part of the industry trend towards smart equipment features for all types of workshop and factory uses.

How do we know that digital controls are an emerging preference for workshop equipment?

It is important to identify customer preferences for workshop equipment, and for Rong Fu this means designing and engineering mill drill and metal cutting bandsaw features that satisfy demand for specific features. This is why we engage with customers to identify trends in the marketplace that help us best meet the emerging needs of the OEM and ODM workshop equipment industry.

Digital controls make workshop machines easier to operate

As workshop machines become more complex with more features, it becomes increasingly important to design control panels to make them more easily understood and easier to use by operators. The example shown above of a CNC machine control panel gives an idea of the complexity of modern workshop equipment, and the need for at-a-glance digital controls.

Why are digital controls a popular choice for mill drills & metal cutting bandsaws?

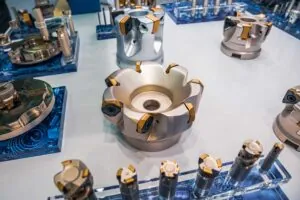

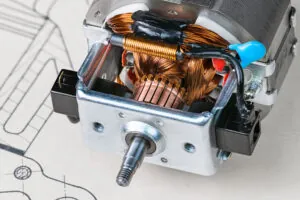

It is not only ease of use that drives digital controls, the changing requirements for workshop equipment in terms of the need to cut and mill new materials are a powerful driver for innovative mill drill technology and product development as well as metal cutting bandsaw design.

- Ease of use for both new and repetitive tasks

- Interfaces that are familiar to a new generation of technology focused customers

- Precision cutting speeds and controls for new material technologies

- Clear visual indicators of cutting settings & progress

Digital controls improve both new and repetitive workshop task management

Another functional benefit of digital controls is the ability to record and reuse verified setting for specific tasks and types of cut, this enables rapid resetting of the machine with standard settings that have been found to be the most appropriate for repetitive tasks, and also lets the operator keep track of the best machine settings for novel materials or tasks.

Machine operators expect digital controls for modern workshop equipment

The current generation of machine operators have grown up with smart phones and the internet, and are used to devices that have touchscreen interfaces, digital controls and screen-based visual feedback instead of more traditional dials, switches and indicator lights. This makes digital controls a familiar and expected technology for mill drills and metal cutting bandsaws today.

Digital controls enable precise speed and cut control for new materials

The adoption of digital controls enables very precise at-a-glance verification of exact speed and cut characteristics, which are a necessity for successful, accurate, clean cutting of CFRP, other composites and advanced alloys. Precision control of machine settings is essential for cutting materials that are heat sensitive or very hard to cut.

Visual indicators of machine setup for mill drills & bandsaws improve performance

Digital controls and screens offer immediate, visual indicators of the machine setup for mill drills and metal cutting bandsaws, and can also give clear indicators of task time and progress. Digital control systems and displays can be customized to offer a wide range of information on machine and job status that gives the operator deeper insights and better capacity to modify and adjust settings for optimum performance.

Why is Rong Fu the best choice for mill drills & metal cutting bandsaws with digital controls?

Our long established reputation for reliable engineering and sophisticated production have made us a popular choice to supply OEM metal cutting bandsaws and mill drills to global customers, and we offer customizations that include digital controls for a wide range of bandsaws and mill drill machines to match consumer demand.

Our attention to the global marketplace and our ability to offer flexible manufacturing and parallel batch production of different models to Toyota Production System standards of reliability and quality make us a highly dependable partner, and our location in Taiwan gives us the excellent supply chains that support just in time shipping to precise schedules.

Contact us to find out more about our award winning range of mill drill machines and metal cutting bandsaws that are designed and engineered to meet industry trends for digital controls and other innovations without compromising on performance, maintenance, precision or durability.