According to the U.S. Bureau of Labor Statistics, fabrication productivity increased by over 20% in the last five years due to technological innovations (source: U.S. Bureau of Labor Statistics). This article examines the specific benefits that horizontal metal cutting bandsaws bring to fabricators. We will explore the design, performance, and adaptability of these machines, with insights drawn from the innovative solutions available at RongFu Industrial.

RongFu Industrial specializes in advanced machinery that delivers superior cutting performance. The discussion below is strictly based on the detailed product information available on the RongFu website, ensuring that every aspect of the article is directly relevant to professionals in the manufacturing industry.

1. Introduction to Horizontal Metal Cutting Bandsaws

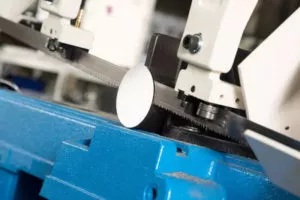

Horizontal metal cutting bandsaws have transformed the metal fabrication process by offering an integrated solution that combines speed with high precision. These machines are engineered to cut through various metal stocks using a scissor-like action that utilizes gravity, hydraulic pressure, or operator force. This design provides rapid, consistent cuts that are essential for demanding fabrication environments.

The robust build of a horizontal band saw allows it to handle a wide range of materials and shapes, reducing the need for multiple specialized machines in a fabrication shop. This consolidation of functions leads to improved workflow and reduced equipment footprints. With features designed to minimize operator fatigue and enhance productivity, the metal cutting band saw remains a cornerstone of modern fabrication facilities.

2. Precision and Efficiency in Metal Cutting Band Saw Operations

A metal cutting band saw offers unparalleled precision, ensuring that each cut is clean and exact. Its innovative mechanism provides a consistent cutting action that minimizes material distortion and waste. The machine’s ability to maintain uniform performance across different metal types makes it indispensable for high-volume production settings.

Efficiency is also a hallmark of the metal cutting band saw. Integrated control systems adjust cutting pressure and speed in real time, allowing the machine to optimize each operation. This results in reduced setup times and lower operational costs, both critical factors in a competitive manufacturing environment. Key benefits include:

- Consistent cutting quality with every operation

- Reduced material waste and post-processing work

- Lower energy consumption through efficient design

By combining precision with efficiency, the metal cutting band saw ensures that every production cycle meets the high standards demanded by professionals in the manufacturing industry.

3. Versatility Across Diverse Fabrication Applications

One of the most compelling attributes of horizontal metal cutting bandsaws is their versatility. These machines are designed to handle a variety of metal types and shapes, making them ideal for fabricators who work with different materials. Whether dealing with thin sheets or heavy-duty bars, the metal cutting band saw provides a reliable solution for precise cutting.

The machine’s design includes a rotating base or vice that permits multiple cutting angles. This feature expands the range of applications, allowing fabricators to adjust the cutting approach without needing additional equipment. Moreover, the integration of a portable band saw option enhances mobility within the workshop, ensuring that the machine can be easily repositioned as production needs change. Benefits of this versatility include:

- Adaptability to different metal types such as steel, aluminum, and more

- Capability to perform complex cuts at various angles

- Efficient use of floor space by reducing the need for multiple specialized machines

The ability to manage diverse applications makes the metal cutting band saw an essential investment for fabricators looking to streamline their operations.

4. Enhancing Operator Efficiency and Safety

Advanced automation features in the metal cutting band saw help improve operator efficiency and overall workplace safety. With automated feed systems and precise digital controls, the machine minimizes manual intervention during cutting operations. This reduction in operator workload leads to improved productivity and consistent quality throughout the production process.

Safety is a top priority in metal fabrication, and modern horizontal band saws incorporate several protective features to safeguard operators. These include emergency stop mechanisms, protective guards, and integrated sensors that monitor the cutting process. Such features help to prevent accidents and equipment damage while ensuring that operators can work in a secure environment. Notable points include:

- Automated systems that reduce the need for constant manual adjustments

- Integrated safety features such as emergency stops and guards

- Enhanced operator comfort through ergonomic design

These measures not only improve productivity but also contribute to a safer and more reliable operating environment, making the metal cutting band saw an optimal choice for fabrication professionals.

5. Core Components and Technological Innovations in the Metal Cutting Band Saw

The performance of a metal cutting band saw is heavily reliant on its core components and the advanced technologies embedded in its design. One of the most critical components is the cutting blade. High-quality Band saw blades used in these machines are engineered to remain sharp and durable, even after prolonged use. This ensures that each cut is executed with maximum precision and minimal wear on the material.

Beyond the cutting blade, the machine incorporates advanced hydraulic systems and reliable drive mechanisms that contribute to its overall performance. By continuously monitoring the Bandsaw blade speed and adjusting it to suit different metal types, the machine optimizes its performance and extends the life of its components. These technological innovations include:

- Precision-engineered blades designed for longevity and accuracy

- Advanced hydraulic controls that ensure optimal cutting pressure

- Reliable drive systems that maintain steady performance under heavy loads

The integration of these components guarantees that the metal cutting band saw consistently delivers the high quality and efficiency required by modern fabricators.

6. Integration of Portable Band Saw Capabilities for Flexible Operations

In today’s fast-paced fabrication environments, flexibility is essential. The inclusion of a portable band saw feature in some horizontal metal cutting bandsaws allows operators to move the machine to different areas of the production facility as needed. This mobility minimizes the need to transport heavy metal stock over long distances, which can be both time-consuming and costly.

The portable aspect of these machines does not compromise their performance; rather, it enhances operational flexibility. A portable metal cutting band saw provides the same level of precision and efficiency as a fixed unit, ensuring that high-quality cuts are maintained regardless of the machine’s location. Key advantages of portable solutions include:

- Flexibility to reposition the saw within the workshop

- Reduced material handling and associated costs

- Consistent cutting performance, whether stationary or mobile

By integrating portable solutions, fabricators can adapt to dynamic production demands while maintaining the high standards expected from a metal cutting band saw.

7. Customization Options and Reliability from a Leading Band Saw Manufacturer

When selecting equipment for metal fabrication, customization is crucial to meet specific operational needs. Partnering with a reputable Band saw manufacturer like RongFu Industrial offers fabricators access to machines that can be tailored to their production requirements. Customization options include adjustable cutting parameters and specialized attachments that allow the metal cutting band saw to be optimized for various applications.

RongFu Industrial is renowned for its commitment to quality and innovation, ensuring that every machine is built to last. Operators can adjust settings such as Bandsaw blade speed to accommodate different metal thicknesses and hardness, which in turn improves cutting precision and reduces waste. Customization benefits include:

- Tailored machine settings for diverse metal types and production needs

- Enhanced longevity through precision adjustments and high-quality components

- Optimized production workflows with specialized machine configurations

By choosing a customized solution from a trusted band saw manufacturer, fabricators can ensure that their metal cutting band saw is perfectly aligned with their operational objectives.

8. Future Trends in Metal Cutting Band Saw Technology

The future of metal cutting band saw technology is promising, with ongoing advancements aimed at enhancing efficiency and precision even further. Continuous innovation in automation and digital control systems is set to revolutionize the way fabricators operate. Future machines are expected to integrate smart technologies that offer real-time monitoring and predictive maintenance, ensuring that the machine performs at its best at all times.

One key area of development is the integration of enhanced connectivity features that link the machine to broader digital manufacturing systems. This connectivity allows for streamlined operations and better control over the production process. Additionally, advancements in cutting tool materials and Band saw blades technology will lead to even longer-lasting and more precise components. Upcoming trends include:

- Increased automation for real-time process adjustments

- Digital connectivity that enables predictive maintenance

- Advancements in material science for superior cutting tools

These technological trends will further cement the role of the metal cutting band saw as a vital piece of equipment in the modern fabrication shop, driving productivity and innovation.

9. Maximizing Production Efficiency with a Metal Cutting Band Saw

A key factor in maximizing production efficiency in any fabrication shop is the integration of a high-performance metal cutting band saw. These machines are designed to operate continuously with minimal downtime, ensuring that each cut is precise and reliable. By streamlining the cutting process, fabricators can reduce waste and optimize material usage, which translates directly into improved productivity.

Moreover, the automation features built into the metal cutting band saw reduce the need for constant manual supervision. Operators can set the machine to work with optimal parameters, freeing them to focus on other critical tasks in the production process. This improved efficiency is a major advantage for busy workshops where every minute counts. Some of the benefits include:

- Continuous, high-quality cutting with minimal interruption

- Reduced operator fatigue through automated controls

- Enhanced material utilization and reduced waste

The overall impact is a smoother production process that boosts efficiency while maintaining the high-quality standards required in advanced metal fabrication environments.

10. Advancing Fabrication Excellence with a Customized Metal Cutting Band Saw

Adopting advanced machine technology is key to staying competitive in the manufacturing industry. A customized metal cutting band saw offers fabricators the flexibility to adjust machine settings according to specific production needs, ensuring every cut meets the highest quality standards. With tailored configurations, these machines can be optimized to process a wide range of metal types and thicknesses efficiently.

RongFu Industrial leads the way in providing these customizable solutions. Their expertise as a Metal band saw manufacturer means that every machine is built with precision and reliability in mind. Fabricators can adjust critical parameters such as Bandsaw blade speed to ensure that each cut is executed flawlessly, thereby enhancing overall production quality. Notable customization features include:

- Adjustable cutting parameters for various materials

- Configurable hydraulic and mechanical systems for optimal performance

- Tailored solutions designed to meet specific production challenges

By investing in a customized metal cutting band saw, fabricators can elevate their operations and achieve a level of precision and efficiency that sets their production apart from the competition.

Advancing Fabrication Excellence with RongFu Industrial

In summary, the advantages of horizontal metal cutting bandsaws are clear for fabricators seeking a blend of precision, efficiency, and versatility. These machines use advanced cutting techniques to deliver rapid, consistent cuts while minimizing material waste and operator fatigue. The metal cutting band saw not only enhances production workflows through automation and customizable settings but also offers flexibility through portable options. Each component—from high-quality Band saw blades to reliable drive systems—works together to ensure optimal performance.

The integration of future technological trends will continue to drive innovation in the field, making the metal cutting band saw even more efficient and indispensable for modern fabrication. By choosing equipment from a trusted partner like RongFu Industrial, fabricators benefit from machines that are built to last and engineered to meet the most demanding production requirements. With customization options available from a leading Band saw manufacturer, every fabricator can achieve the operational excellence necessary to succeed in a competitive marketplace. RongFu Industrial stands as a globally recognized and respected band saw and mill drill machine manufacturer, committed to advancing the quality and productivity of metal fabrication operations.