Discover better performance, efficiency and ease of use with Rongfu DC motors

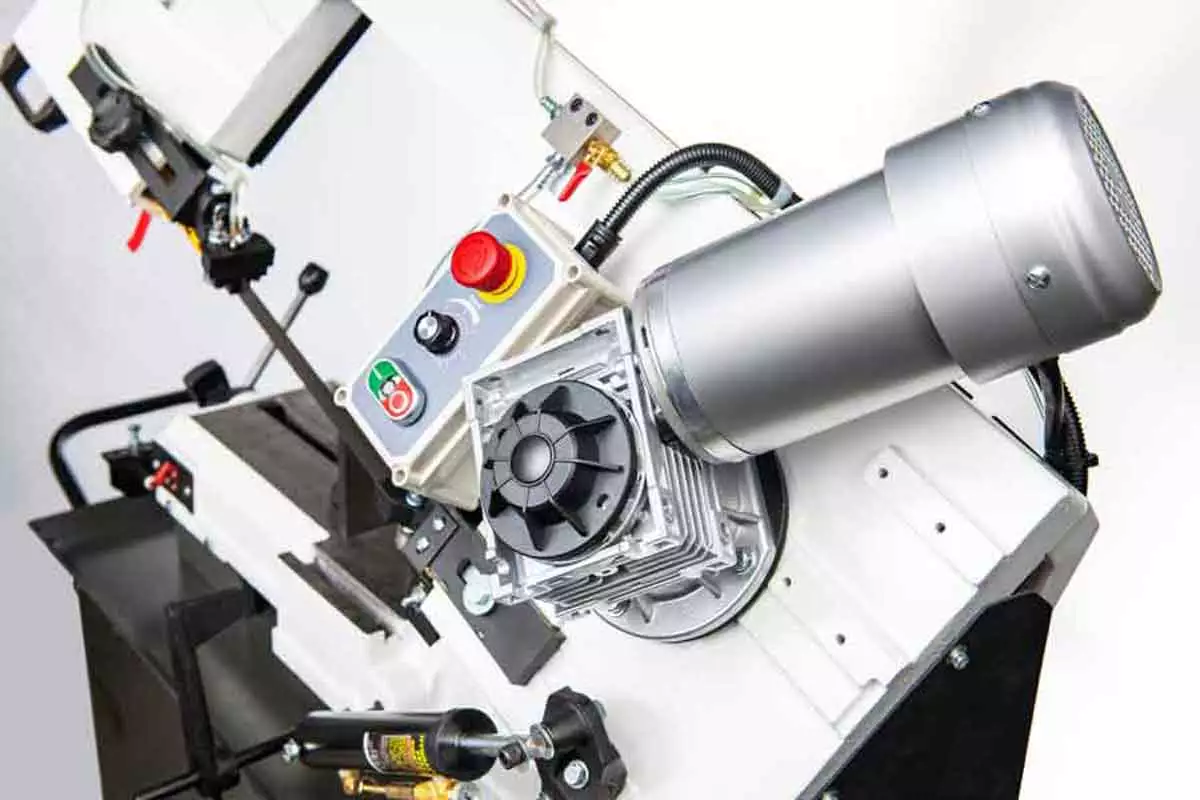

We offer a comprehensive selection of DC motors with our bandsaws. DC motors for bandsaws give you high performance and efficiency gains, and can be easier to install and operate than AC motors. DC motors are smaller and cheaper to run for the same power output. The low vibration and high starting torque of DC motors increases cutting precision.

Table of Contents

Advantages of DC motors

- Small size and weight for compact designs

- Easy installation

- Pulse Width Modulation (PWM) control enables motor torque compensation for stepless operation

- No need to change reduction ratio

- High torque output at low and high speeds

- Very high output efficiency

- Low temperature operation

- Significant energy savings

- PWM control ensures consistent cutting speed

- Low vibration operation makes sawing action more stable and results in smoother cuts

DC motors for bandsaws offer many operational advantages. Their compact size and weight for the same power output enables compact designs with smaller footprints but the same cutting capability as larger AC powered bandsaws. Compact and balanced designs with stepless PWM control reduce vibration and increase the precision of the bandsaw, resulting in smoother cuts.

DC motors are easy to install as they do not require complicated switching devices or mechanical transmissions. PWM control of the motor provides stepless high and low speed regulation of the band saw, and compensates for the motor output torque. This enables fixed speed cutting at high or low speed operation, making the cutting surface smooth.

Comparison of DC & AC motors

AC Motors

Advantages of AC Motors

- Simple design

- Low cost

AC motors look like a good choice because of their low cost and simple design. Unfortunately they have many disadvantages compared to DC motors.

Disadvantages of AC Motors

- Inefficient: single phase motor efficiency ratings of 50-60%

- Uses a lot of power

- Can only run at high speed

- Noisy and subject to vibration problems

- High operating temperature

- Require gearboxes / speed reducers

AC motors are very inefficient and consume a lot of power, with a maximum efficiency of 50-60%. Due to operational frequency limitations they can only be run at high speed, which increases noise and vibration and makes the motor run hot. At high operating temperatures motors become increasingly inefficient and have a reduced lifespan.

Motor vibration reduces cutting accuracy unless the bandsaw is very heavy, and AC motors are large. This makes AC motors unsuitable for compact and portable designs or installations where space is limited. AC motor control is more difficult than DC motor control and gearboxes or speed reducers are usually required.

DC Motors

Advantages of DC Motors

- Stable at high speeds

- Constant operating temperature without overheating

- Significant reduction in energy use

- Easy to install and control

- Reliable

- Environmentally friendly

DC motors are very stable even at high speed operation and operate at lower temperatures than AC motors.

Saving energy reduces operational costs and is more environmentally friendly, reducing the demand for power generation. The high efficiency of DC motors and lower operating temperatures can also make them more reliable and longer lasting than AC motors.

Disadvantages of DC Motors

- Higher initial cost

DC motors have a higher initial cost than AC motors, but they are much cheaper to run and often last longer. DC motors are less expensive than AC motors when you consider the higher operational cost of using AC motors for the same task.

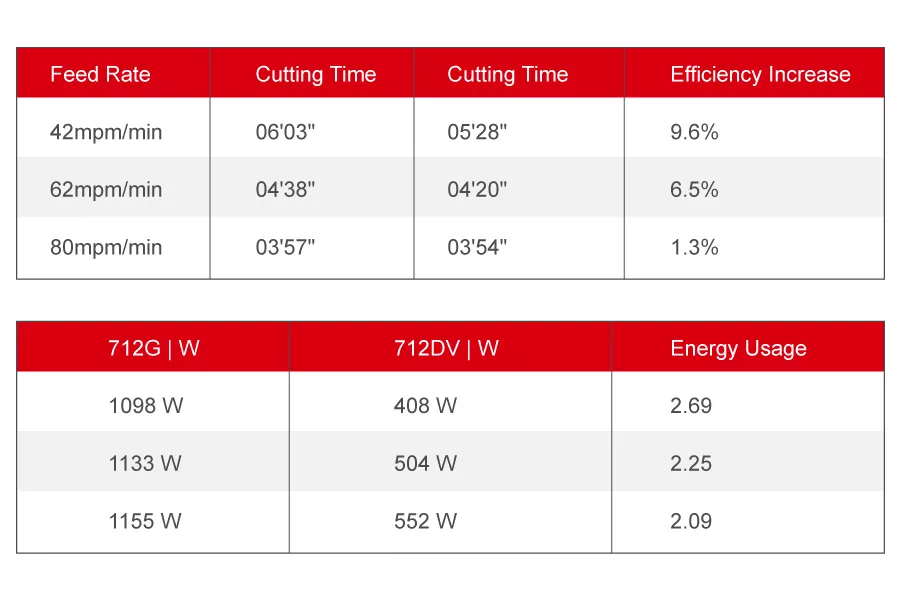

Performance Test Comparison of AC & DC Motors

Features of DC Motors for Bandsaws

- Motor maintains stable torque at any speed, no speed reduction necessary.

- Stepless blade speed change for easy cutting speed control

- Compact installation

- Very high transmission efficiency with low loss.

- Overload protection increases saw band life and reduces wear

DC motors have a high, stable, starting torque output at any speed. This enables continuous, stepless blade speed control for ease of use and increased precision. The compact design of DC motors enables small footprints for machines, increases their portability and makes them suitable for installation in smaller spaces as well as reducing shipping and installation costs.

Transmission efficiency of DC motors is very high, and in some installations can reach up to 97%, which reduces energy consumption. DC motors also feature overload protection, which increases saw band life and reduces wear as the motor stops and enables the machine to be reset before breakages occur.

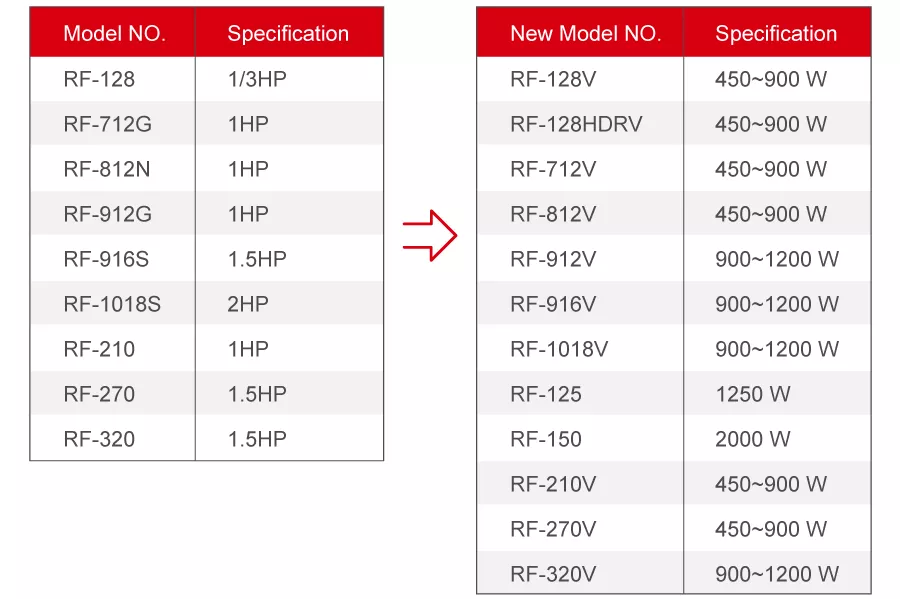

Our Range of DC Motors

How We Can Help

We welcome any enquiry about our services and capabilities and are always ready to discuss your specific needs and answer any questions you may have. Our experienced in-house design team has a wealth of knowledge available to help you find the best solution to meet your equipment requirements.

Please contact us if you have any questions or would like further information.