The metal cutting bandsaw market in 2025 is moving from AC motors to DC motors, and brands are benefitting from expert ODM with long experience of metal cutting bandsaw manufacturing to keep up with this market opportunity. Rong Fu is an OEM and ODM of metal cutting bandsaws with established design and engineering capabilities that help existing and emerging brands to expand their DC motor metal cutting bandsaw portfolio to match customer demands.

Table of Contents

Why are customers looking for DC motors for metal cutting bandsaws?

Customers want metal cutting bandsaws with DC motors for several reasons, the most important are convenient speed control, reduced energy consumption, and high torque. End users also like the smaller size and reduced weight of DC motors when choosing between purchase options for portable metal cutting bandsaws. These factors make modern, high performance, reliable DC motors an excellent addition to any metal cutting bandsaw retail catalog in 2025.

What are 8 benefits of DC motors for bandsaws compared to AC motors?

- DC motors offer very precise speed control options.

- Stepless motor torque compensation improves cutting quality

- DC motors deliver more torque at start than an AC motor

- DC motors are smaller than an AC motor with an equivalent rating

- DC motors are more efficient than AC motors.

- Stable speed and reduced vibration creates cleaner cuts

- DC motors can be started and stopped, and reversed, extremely quickly

- Some DC motor bandsaws do not need a gearbox

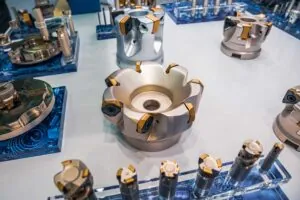

Precise speed control for DC motors using voltage control

DC motor speed is voltage controlled, which makes it very easy to design and manufacture a variable, continuous, stepless, speed control for metal cutting bandsaws. Simple voltage control systems can be included in new touch screen control panels that are proving popular with end users. Pulse Wave Modulated (PWM) controllers enable stepless motor torque compensation for DC motors for smoother cutting under changing loads.

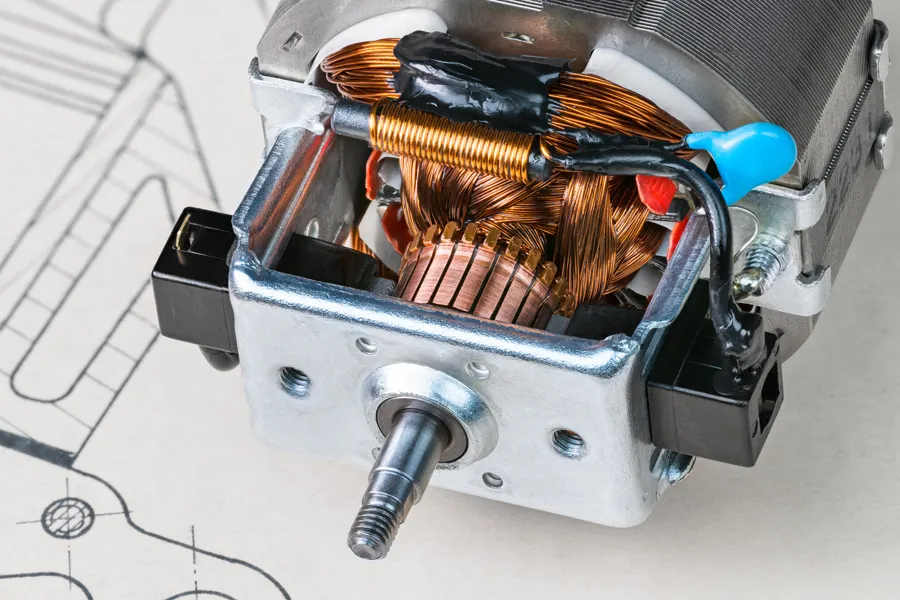

High power density delivers more torque for a smaller, lighter DC motor

DC motors have a higher power density than AC motors, which means a smaller motor can do the same work, and deliver higher torque, reducing size and weight. Because of this, portable DC motor metal cutting bandsaws are lighter and more customer friendly than AC motor metal cutting bandsaws.

Efficient DC motors are more stable & consume less energy

The speed stability and low vibration of DC motors increases cutting quality. Single phase AC motors are less stable and only 50-60% efficient, which makes DC motors a much better choice for domestic and small workshop machinery. Standard DC motors have 80% or better efficiency ratings, which significantly reduces operating energy costs.

Rapid start-stop & reverse control compared to AC motors

The high torque, high power and built in magnets of DC motors allow you to start, stop and reverse very quickly without a gearbox, and return to full speed much more rapidly than an AC motor. This increases the safety, simplicity and versatility to a DC motor equipped machinery compared to AC motors.

DC motors for smaller bandsaws may not require a gearbox

For smaller metal cutting bandsaws, like the portable Rong Fu RF-150V shown above, DC motors are sufficiently powerful that it is possible to design a bandsaw that has no gearbox. The RF150-V relies on the high torque of a 450W DC motor and uses a digital electronic speed regulator to smoothly adjust the cutting speed of the bandsaw. This is an improvement over AC motors, which almost inevitably require a gearbox in the transmission line, adding weight and complexity.

Can ODM partners produce good DC motor metal cutting bandsaws?

Like any consumer product, a DC motor metal cutting bandsaw benefits from good fundamental design principles and engineering capabilities. When you want to include DC motors in your metal cutting bandsaw range, it makes perfect sense to approach a specialist Original Design Manufacturer (ODM) with broad industry experience, existing access to cost effective supply chains and the tooling and workforce skills required for manufacturing and assembly.

What are 5 reasons to work with an ODM metal cutting bandsaw manufacturer?

- Prior experience and existing skills, tooling and workforce capabilities make it highly cost effective to work with ODM metal cutting bandsaw manufacturers.

- You can significantly reduce research and development costs and retain profits.

- ODM metal cutting bandsaw manufacturers can get your new products to the market much more quickly than your competitors.

- Rapid product development increases adaptability to respond to market changes and changing consumer preferences, like the demand for more DC motor metal cutting bandsaws.

- ODM engineers have considerable background experience and expertise that can be used for rapid customization and to enable products to be rapidly modified to meet specific requirements.

Rong Fu ODM for DC motor metal cutting bandsaws

Rong Fu has more than 50 years experience in manufacturing metal cutting bandsaws and mill drill machines. This gives us skills and capabilities in-depth to create award winning designs for ODM DC motor metal cutting bandsaws alongside a wide range of models and options for our globally recognized OEM brands. Just look at the example of our 9” RF-270, pictured above, which can be supplied with either AC or DC power and various cutting bed upgrade options and original design features.

Our expertise in DC motor bandsaws creates an opportunity to include or expand your portfolio of consumer and workshop machines without incurring significant development costs. Contact us to discover how you can benefit from partnering with Rong Fu to build high quality ISO certified and globally compliant ODM DC motor metal cutting bandsaws.