Definition of Work Offset

Why It Matters for Band Saw and Mill Drill Machines

Related Terms

CNC Coordinates G54-G59 Tool Offset Datum Point Fixture Setup Machine ZeroFAQ

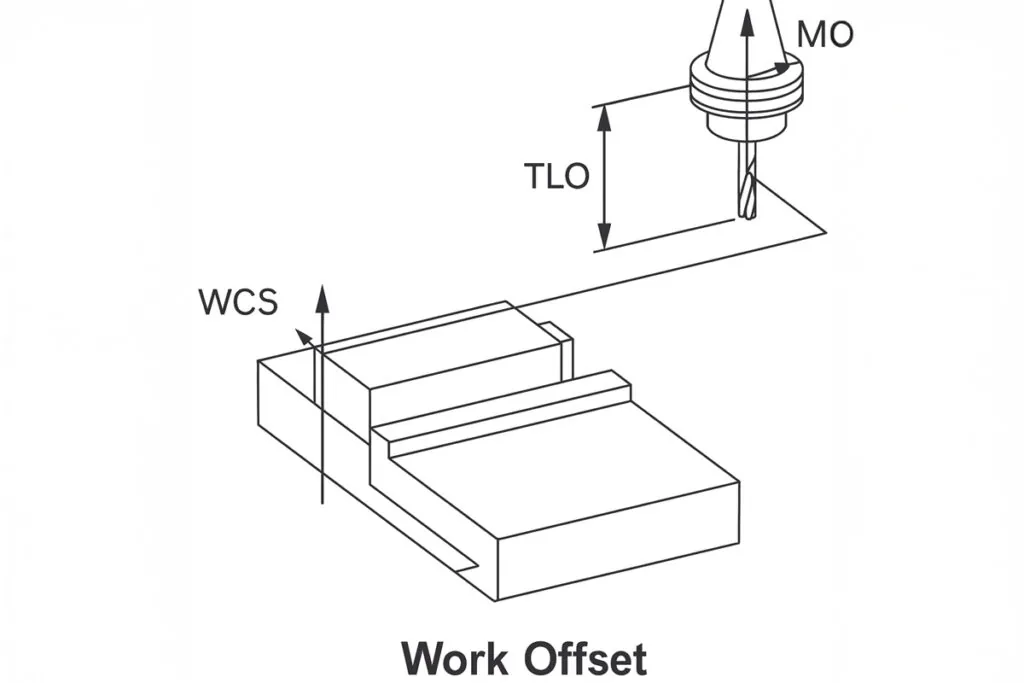

What is the difference between work offset and tool offset?

Work offset defines the position of the workpiece, while tool offset accounts for the length and diameter of the cutting tool. Both are required for precise machining. If either is wrong, the CNC machine cannot cut accurately. Work offsets tell the machine where the part sits, and tool offsets ensure the tool contacts at the correct depth and position. Together they guarantee dimensional accuracy.

How do machinists set a work offset?

A machinist sets a work offset by finding a reference point on the workpiece, such as a corner or a hole, then recording its coordinates into the CNC controller. Tools like edge finders, dial indicators, or probing systems are often used for accuracy. Advanced machines may have automatic probing that sets offsets with little manual input.

Can multiple work offsets be used in one job?

Yes, multiple work offsets can be used, often identified as G54, G55, and so on. This allows you to machine multiple parts in a single setup or handle different operations on the same part. It increases efficiency, reduces downtime, and simplifies machining when working with complex fixtures.

What happens if a work offset is wrong?

If a work offset is wrong, the machine will cut features in the wrong place or even collide with the part. This can cause scrapped workpieces, damaged tools, and lost production time. That is why verifying offsets before machining begins is critical. Many operators use test runs or dry runs to confirm accuracy.

Why are work offsets important in automation?

In automated or batch production, accuracy and repeatability are vital. Work offsets make sure each part is machined consistently without manual resetting. This saves operator time, reduces error, and allows unattended machining with confidence. Correct offsets are the foundation of efficient CNC automation.