Definition of Step Over

Why It Matters for Band Saw and Mill Drill Machines

Related Terms

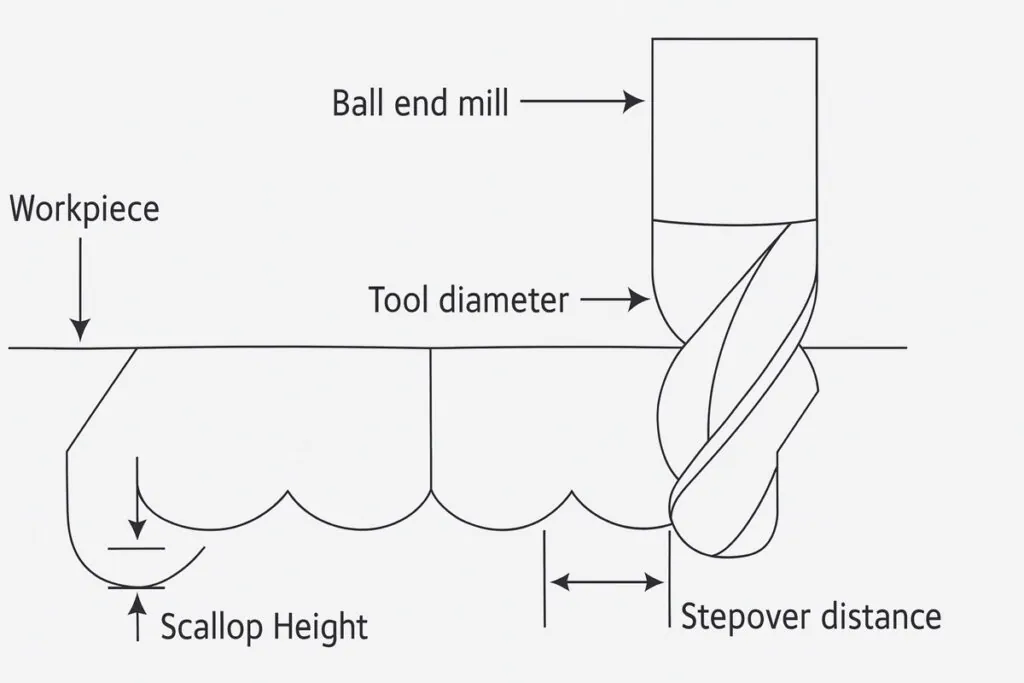

Scallop Height Toolpath Roughing Pass Finishing Pass Feed Rate Surface FinishFAQ

What is the best step over percentage?

The best step over percentage depends on the operation. Roughing typically uses 40–70% of tool diameter to maximize material removal, while finishing uses 5–20% to achieve smooth surfaces. Choosing the right percentage depends on your priorities: speed or surface quality.

How does step over affect surface finish?

Step over directly affects the scallop height left behind by the cutter. A smaller step over leaves smaller scallops, producing a smoother finish. A larger step over removes material faster but leaves deeper marks, which may require extra finishing passes to correct.

Can the wrong step over damage tools?

Yes, an incorrect step over can increase tool stress. Too large a step over causes heavy cutting loads, heat buildup, and premature tool wear. Too small a step over can cause rubbing and reduce tool efficiency. Balanced settings extend tool life and improve cutting performance.

How do you select step over for different materials?

Harder materials like stainless steel may need smaller step overs to reduce tool stress, while softer materials like aluminum can tolerate larger step overs. Plastics often require moderate settings to prevent melting or tearing. Always test and adjust based on your material.

What happens if the step over is too small?

If the step over is too small, machining time increases dramatically without significant improvement in surface quality. Tools may wear prematurely due to rubbing rather than cutting. This reduces efficiency and increases production costs.