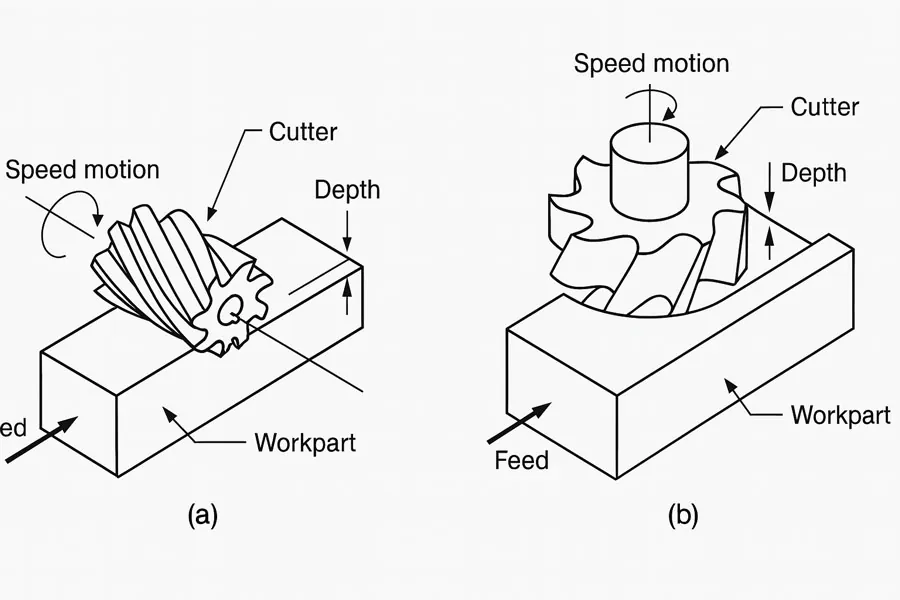

Definition of Slab Milling

Why It Matters for Band Saw and Mill Drill Machines

Related Terms

Face Milling Climb Milling Conventional Milling Carbide Inserts Roughing Pass ToolpathFAQ

Which machines support slab milling?

Slab milling works best on horizontal milling machines and mill drill machines with power feeds on the table or spindle. Look for machines offering rigid construction, precise power-feed control, and sufficient horsepower. Some vertical mills with robust table feed drives can also perform light slab milling. You need a machine that maintains stability under wide-cutter loads and offers adjustable feed rates to match cutter diameter and material hardness.

How do I select the right cutter for slab milling?

Choose a cutter with a diameter suited to the workpiece width and enough carbide or indexable inserts to share the load. Wider cutters (100–200 mm) remove more material per pass but require more machine power. Inspect tooth geometry: positive rake angles suit softer metals, while neutral or slight negative rake is safer for harder alloys. Verify insert grade for material compatibility and ensure you have enough reserve stock for multiple re-grinds.

What cutting parameters work best for slab milling?

Start with a moderate spindle speed and a feed per tooth of 0.1–0.2 mm, then adjust based on cutter diameter and material. Deeper cuts up to half the cutter diameter boost material removal but increase force. Balance depth and width of cut to match your machine’s rigidity. Monitor chip shape and surface finish: long, stringy chips suggest too light a cut, while powdery chips indicate excessive engagement or dull inserts.