Definition of Gang Milling

Why It Matters for Band Saw and Mill Drill Machines

Related Terms

Arbor Mounting Multi-Cutter Setup Horizontal Milling Slot Milling Shoulder Milling Workholding FixturesFAQ

How is Mill Drill Machine Gang Milling set up for multiple cutters?

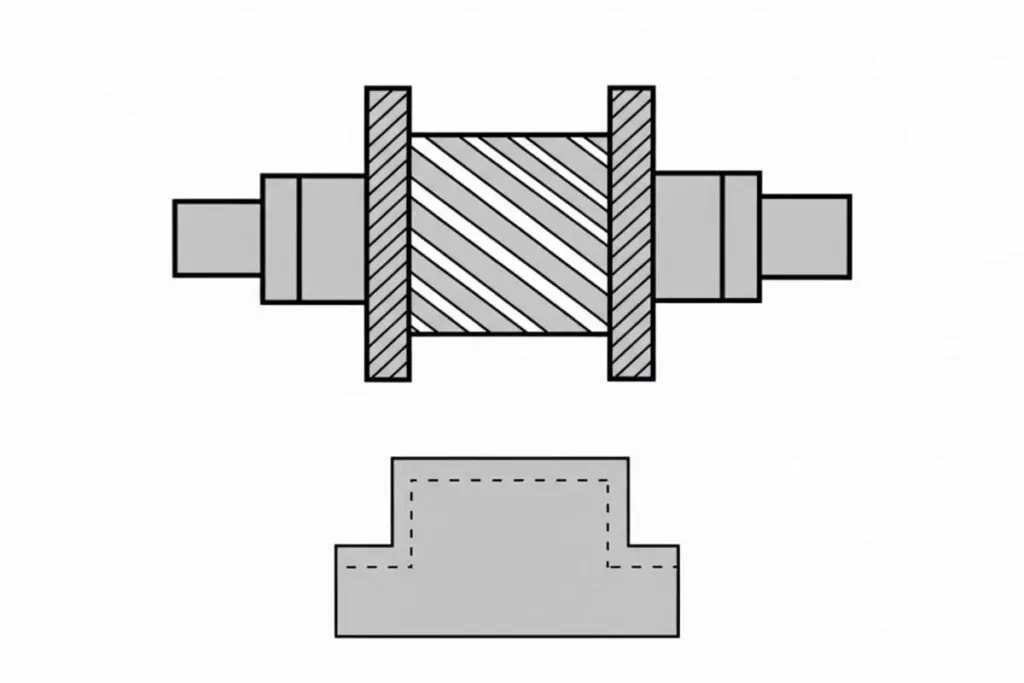

Mill Drill Machine Gang Milling uses a shared arbor or extended spindle setup to mount several cutters with spacers in between. The setup must ensure precise axial and radial alignment. Proper fixturing is crucial to avoid deflection due to the increased load from multiple cutters.

Can vertical Mill Drill Machines perform gang milling?

While more common on horizontal mills, vertical mill drill machines can perform gang milling using a horizontal arbor attachment or extended spindle configurations. However, the machine must be rigid and properly fixtured to handle the combined cutting forces.

What types of operations are best suited for Mill Drill Machine Gang Milling?

Mill Drill Machine Gang Milling is best for repetitive machining tasks like creating parallel slots, stepped shoulders, or continuous profiles on long workpieces. It's especially effective in producing identical parts in a batch setup where time and consistency are critical.

What are the limitations of using Mill Drill Machine Gang Milling?

Limitations include the increased demand for machine rigidity, alignment precision, and advanced fixturing. Not all mill drill machines can accommodate the arbor length or handle the added cutting load. Vibration control and cutter spacing also become more challenging.