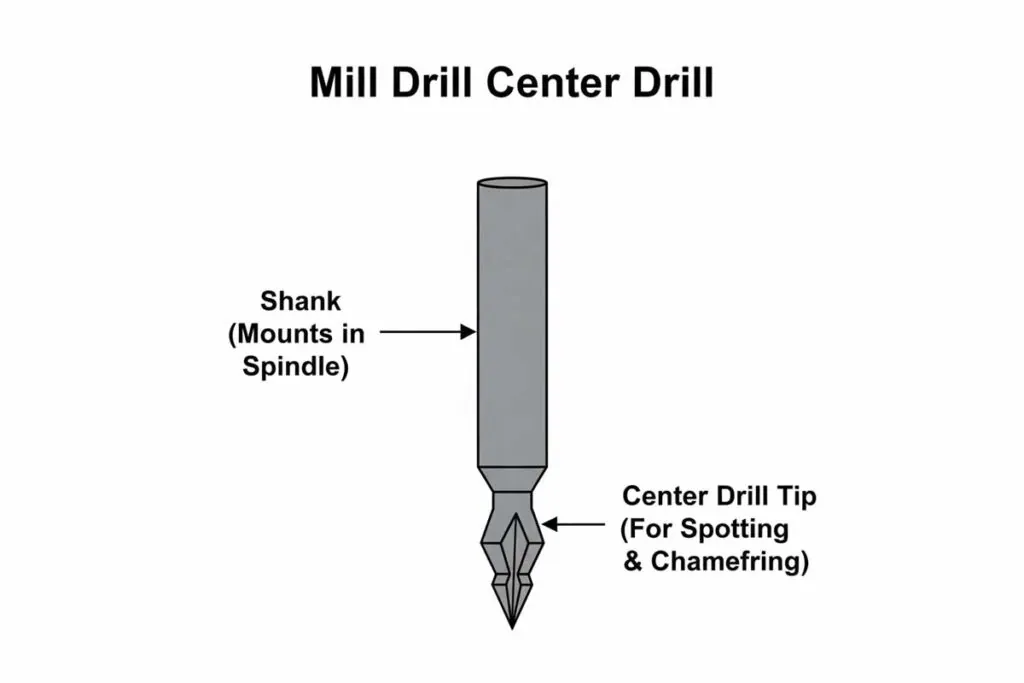

Definition of Center Drill

Why It Matters for Band Saw and Mill Drill Machines

Related Terms

Spot Drill Twist Drill Pilot Hole Drilling Accuracy Tool Deflection Chamfering ToolFAQ

When should a Mill Drill Machine Center Drill be used before drilling?

A Mill Drill Machine Center Drill should be used whenever accurate hole placement is required, particularly in hard materials or on angled surfaces. It ensures that the twist drill starts precisely, minimizing deflection and positional errors in the final hole.

What are the differences between a Mill Drill Machine Center Drill and a spot drill?

While both create starting points for drilling, a Mill Drill Machine Center Drill has a pilot tip and is stiffer, making it suitable for creating lathe centers as well. A spot drill lacks the pilot and is designed purely for creating shallow guide holes with better surface finishes.

How deep should a Mill Drill Machine Center Drill hole be?

The depth depends on the size of the follow-up drill, but typically, only the conical section of the Mill Drill Machine Center Drill is used. Overdrilling can damage the tip or cause chatter. A depth of 1.5 to 2 times the pilot diameter is often sufficient.

Can a Mill Drill Machine Center Drill be used for countersinking?

Only to a limited extent. While the wider section resembles a countersink, Mill Drill Machine Center Drills are not designed for finish-quality countersinking. For consistent results, a dedicated countersink tool should be used instead.