Definition of Climb Milling

Why It Matters for Band Saw and Mill Drill Machines

Related Terms

Conventional Milling Feed Rate Chip Load CNC Machining Tool Wear Machine RigidityFAQ

What is the key difference between climb milling and conventional milling?

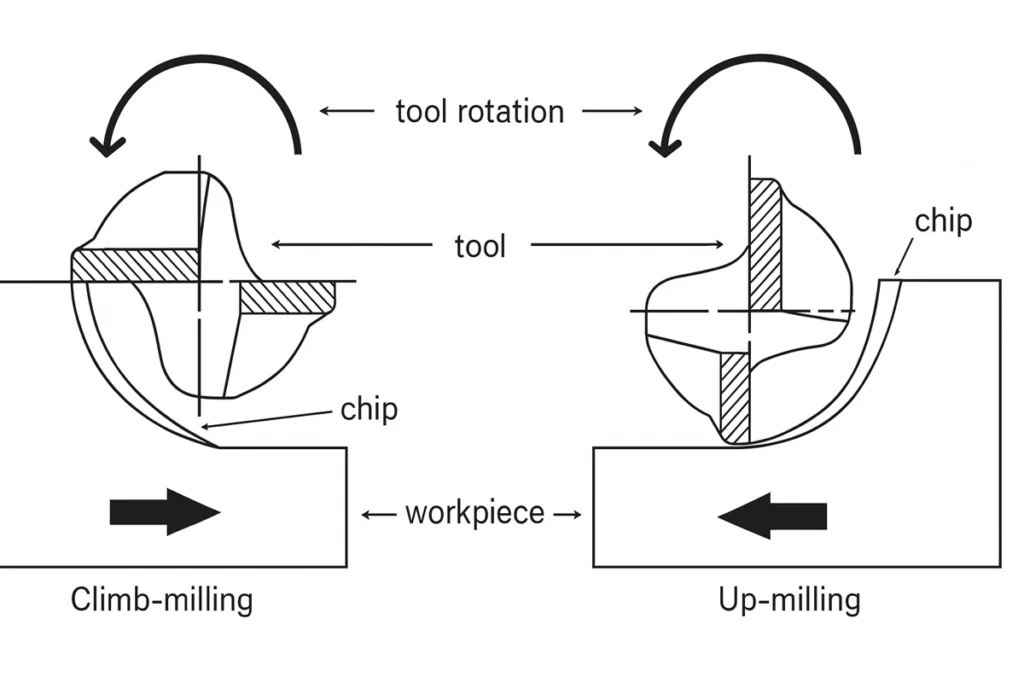

The key difference lies in the direction of tool rotation relative to feed. In climb milling, the tool rotates with the feed, cutting from thick to thin, which reduces friction and heat. In conventional milling, the cutter opposes the feed, starting at zero thickness, which causes rubbing and higher tool wear. This is why climb milling often produces smoother finishes and longer tool life, especially in CNC environments where backlash is controlled.

Does climb milling increase tool life?

Yes, climb milling usually increases tool life because the cutting action reduces rubbing and distributes forces more efficiently. The thick-to-thin chip formation prevents heat buildup at the cutting edge, lowering wear. This extends the useful life of carbide and high-speed steel tools. However, if your machine has backlash, the cutter can grab and damage the tool, so proper machine condition is essential.

What are the risks of climb milling on older machines?

On older or manual milling machines with noticeable backlash, climb milling can pull the workpiece into the cutter unexpectedly. This may cause chatter, dimensional errors, or tool breakage. For this reason, many machinists use conventional milling on less rigid equipment. Climb milling is best reserved for CNC machines with ball screws and tight backlash control.

Which materials benefit most from climb milling?

Materials such as aluminum, brass, and mild steel benefit most because the reduced heat improves surface finish and reduces burr formation. Hardened steels and alloys can also be machined with climb milling when using coated carbide tools, as the lower friction improves tool life. Castings with scale or rough surfaces are better suited to conventional milling to avoid tool grabbing.

How does climb milling affect surface finish?

Climb milling often produces a better surface finish compared to conventional milling. Because the cutter exits the material at zero thickness, it leaves cleaner edges with less tearing or burrs. This is especially important for finishing passes. Still, proper fixturing and rigidity are critical to prevent vibration that can spoil the finish.