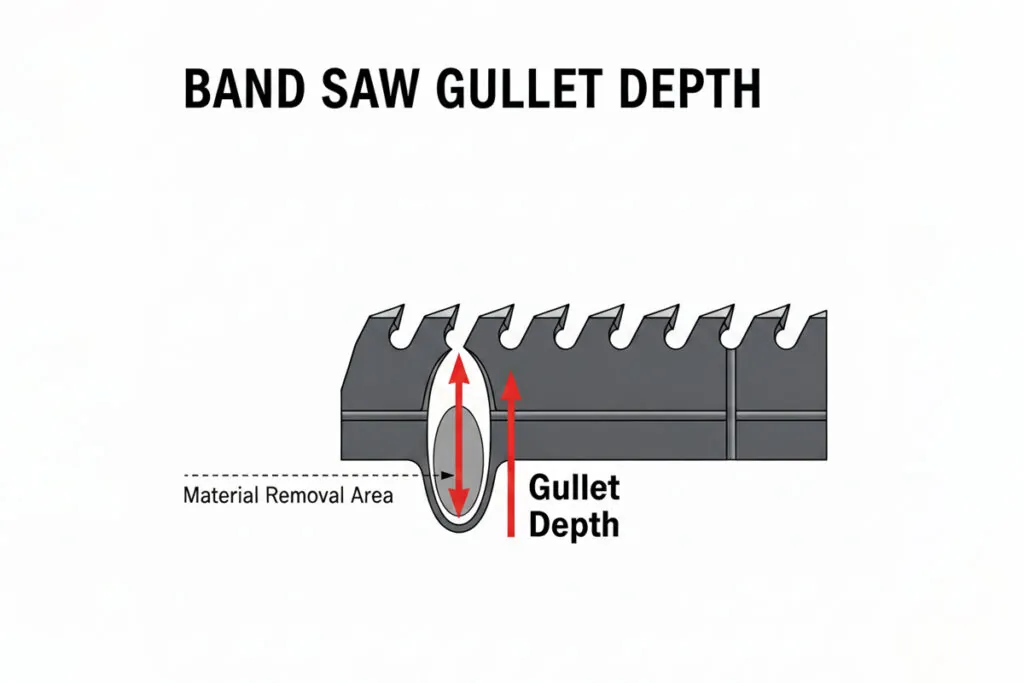

Definition of Gullet Depth

Why It Matters for Band Saw and Mill Drill Machines

FAQ

How does band saw gullet depth affect cutting performance in thick materials?

Band saw gullet depth becomes critically important when cutting thick workpieces because chip volume increases proportionally with material cross-section. Each tooth must transport its accumulated chips through the entire cut depth before exiting the kerf. Inadequate gullet depth in thick sections causes premature chip packing, where the gullet fills completely before the tooth completes its pass. Packed gullets create multiple problems: increased cutting forces, excessive blade heating, poor surface finish, and accelerated tooth wear. For thick sections, operators should select coarse pitch blades (2-3 TPI for sections over 4 inches) which inherently provide deeper band saw gullet depth. Visual inspection of chips exiting the cut provides feedback; chips should flow freely rather than compressing into dense pucks, indicating sufficient gullet capacity.

What is the relationship between band saw gullet depth and tooth pitch specifications?

Band saw gullet depth correlates inversely with tooth pitch; fewer teeth per inch means greater spacing between teeth and consequently larger gullets. A 2-3 TPI blade designed for structural cutting features gullet depths of 0.4-0.6 inches, while a 14-18 TPI blade for thin-wall tubing has gullet depths of only 0.06-0.08 inches. This relationship exists because blade manufacturers optimize gullet geometry for the intended application range of each pitch category. Coarse pitch blades with deep band saw gullet depth excel at cutting thick, solid sections where chip volume per tooth is high. Fine pitch blades with shallow gullets suit thin materials where maintaining at least three teeth in the cut ensures smooth cutting action. Understanding this correlation helps operators select appropriate blade pitch based on workpiece dimensions and chip evacuation requirements.

How can you identify when band saw gullet depth is insufficient for the cutting application?

Insufficient band saw gullet depth manifests through several observable symptoms during cutting operations. Primary indicators include chips exiting the cut in compressed, dense packs rather than loose, curled formations, suggesting the gullets filled to capacity. Cutting rate decreases noticeably as packed gullets prevent efficient material removal. Blade temperature rises excessively due to friction from recutting packed chips. Surface finish deteriorates, showing burnishing or scoring marks. Cutting noise changes to a higher-pitched sound as teeth struggle against chip obstruction. The blade may also track poorly or develop premature tooth wear on the gullet radii. To remedy these conditions, switch to a coarser pitch blade with greater band saw gullet depth, reduce feed rate to decrease chip load per tooth, or verify cutting fluid delivery adequately cools and lubricates the cutting zone.