Definition of Blade Kerf

Why It Matters for Band Saw and Mill Drill Machines

Related Terms

Band Saw Tooth Pitch Band Saw Set Pattern Band Saw Blade Tension Band Saw Carbide Blade Inserts Band Saw Cutting Speed Band Saw Feed RateFAQ

How does Band Saw Blade Kerf affect cutting efficiency?

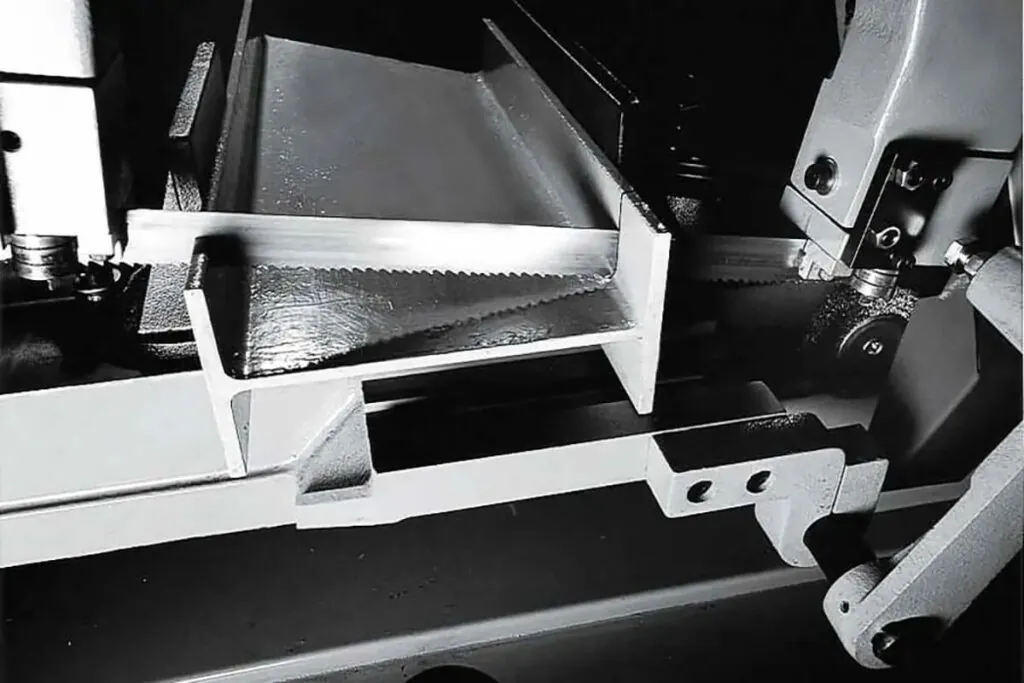

Band Saw Blade Kerf influences cutting efficiency by determining the amount of material removed per pass. A wider kerf increases the cutting load, power consumption, and heat generation, while a narrower kerf requires less effort but demands precise blade alignment to avoid binding. For optimal efficiency, kerf should be matched to material hardness, blade type, and machine stability.

Can Band Saw Blade Kerf be reduced without losing accuracy?

Band Saw Blade Kerf can be reduced through narrower blade bodies and optimized set patterns, but machine rigidity and guide alignment must be excellent to prevent deflection. Carbide-tipped blades or precision-ground tooth profiles can allow smaller kerfs while maintaining accuracy, provided that feed rates and coolant flow are properly controlled.

How does tooth set pattern influence Band Saw Blade Kerf?

Tooth set pattern determines the lateral offset of teeth from the blade body, which in turn defines the kerf width. Alternating, raker, or wavy set patterns each create different kerf profiles. A more aggressive set increases kerf and clearance, which benefits chip evacuation but raises cutting load.