Definition of Tool Presetting

Why It Matters for Band Saw and Mill Drill Machines

Related Terms

Tool Offset Z-Axis Calibration Touch Probe Tool Length Compensation Tool Library Machining Setup TimeFAQ

Why is Mill Drill Machine Tool Presetting important for multi-tool operations?

Mill Drill Machine Tool Presetting ensures each tool’s length and offset are known in advance, preventing errors during tool changes. This is essential when using multiple tools in a single program, where even small discrepancies in Z-axis position can lead to scrapped parts or surface mismatches.

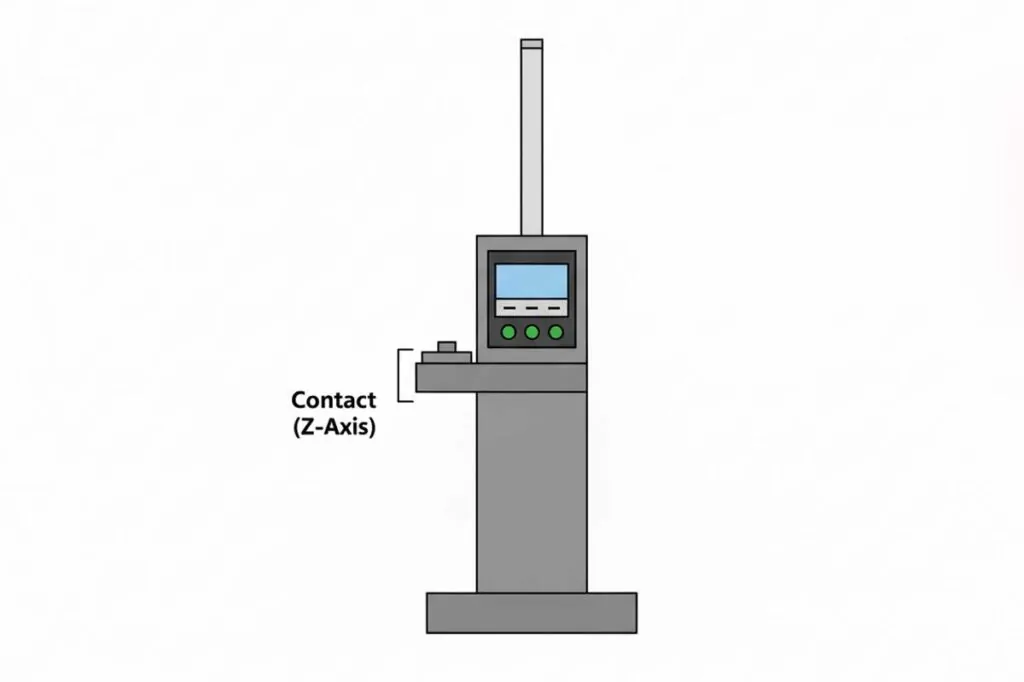

What methods are used for Mill Drill Machine Tool Presetting?

Common methods include using dial indicators, edge finders, or height gauges for manual presetting. CNC machines often use tool presetters or touch probes to automate this process. The method used depends on machine capability and required precision level.

How does Mill Drill Machine Tool Presetting affect machining accuracy?

Accurate tool presetting ensures correct tool length and diameter data is used by the machine controller. This prevents overcutting or undercutting, maintains programmed feature depths, and improves surface quality by reducing manual Z-axis compensation errors.

What are the risks of skipping Mill Drill Machine Tool Presetting?

Omitting tool presetting can lead to inconsistent tool depths, damaged parts, broken tools, and wasted material. It also increases setup time and operator workload. For CNC machines, uncalibrated tools can cause fatal program errors or collisions.