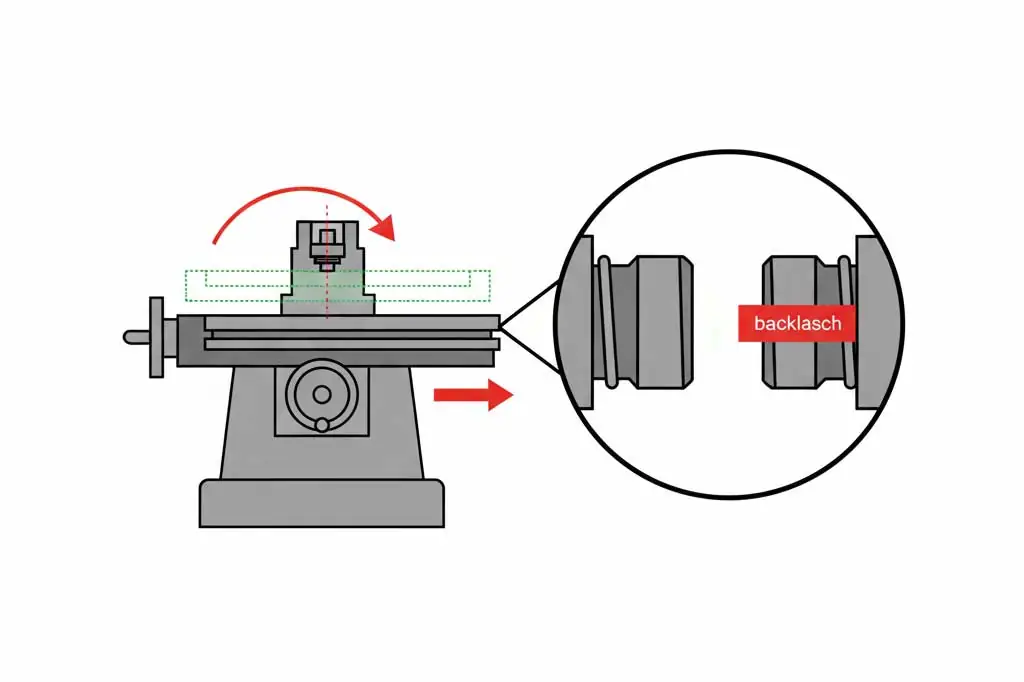

Definition of Backlash Compensation

Why It Matters for Band Saw and Mill Drill Machines

Related Terms

Lead Screw Table Movement Climb Milling CNC Compensation Anti-Backlash Nut Positioning AccuracyFAQ

How does Mill Drill Machine Backlash Compensation improve milling accuracy?

Mill Drill Machine Backlash Compensation eliminates the effects of lead screw slack when changing direction. By accounting for mechanical play, it ensures the cutting tool follows precise tool paths, particularly during complex interpolation or symmetrical features. This results in tighter tolerances and better surface finishes.

What are typical methods of Mill Drill Machine Backlash Compensation?

Typical methods include using anti-backlash nuts, dual-nut assemblies with spring tension, or digital compensation in CNC systems. For manual machines, operators often overshoot and then reverse into position to preload the screw. Each method aims to negate positional lag due to thread clearance.

Can Mill Drill Machine Backlash Compensation be adjusted manually?

Yes, on manual mill drill machines, backlash is often handled by operator technique. This involves always approaching the desired position from the same direction to preload the lead screw. Regular inspection and tightening of the gibs and lead screw nut also help minimize backlash.

How much backlash is acceptable in Mill Drill Machines?

Acceptable backlash varies by application. For general machining, 0.002"–0.005" may be tolerable. For high-precision work, less than 0.001" is desirable. Excessive backlash compromises accuracy and may necessitate mechanical or control-based compensation.