Definition of Quill Feed

Why It Matters for Band Saw and Mill Drill Machines

Related Terms

Quill Travel Fine Feed Control Spindle Lock Depth Stop Boring Head Column MovementFAQ

How does Mill Drill Machine Quill Feed improve drilling precision?

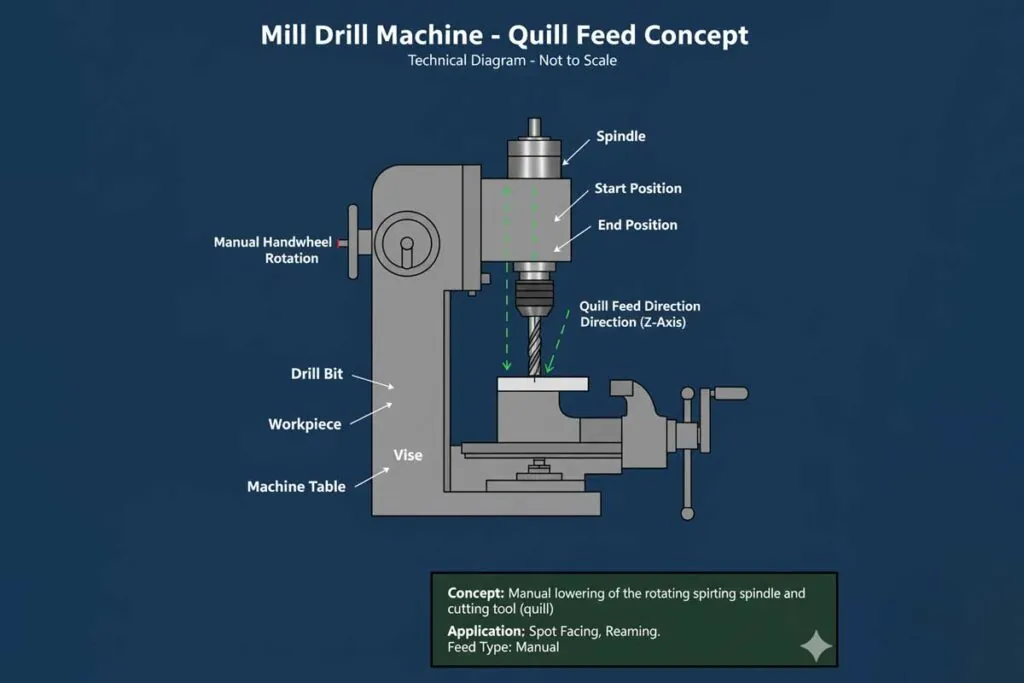

Mill Drill Machine Quill Feed allows the operator to move the spindle vertically without repositioning the head, which maintains machine alignment and enables precise depth control. This direct axial motion is crucial when drilling holes to exact depths, especially in jig setups or repetitive production tasks.

What is the difference between manual and power Mill Drill Machine Quill Feed?

Manual Mill Drill Machine Quill Feed uses a lever or handwheel for operator-controlled movement, offering better tactile feedback for sensitive operations. Power quill feed automates this motion, improving consistency and reducing operator fatigue in high-volume drilling applications. However, manual feed often provides better control in delicate work.

When should the fine feed be used on a Mill Drill Machine Quill Feed?

Fine feed should be used on a Mill Drill Machine Quill Feed when performing operations requiring high accuracy, such as boring, reaming, or spot facing. The slow, controlled movement prevents tool chatter and enhances finish quality. It is particularly important in materials that are prone to work hardening or distortion.

What are the typical travel limits of a Mill Drill Machine Quill Feed?

Mill Drill Machine Quill Feed typically offers travel ranges between 2 to 5 inches, depending on the model. This limited travel is ideal for precision drilling but may require repositioning or table adjustment for deeper operations. Excessive use beyond travel limits can affect feed accuracy and wear quill components.