What are the factors affecting mill drill product development?

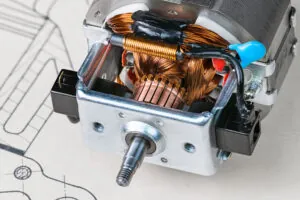

Rong Fu has extensive experience in OEM and ODM mill drill product development for our global clients, from gear head workhorses like the RF-45 pictured above, to advanced, touch screen controlled machines. We follow trends and customer preferences to identify the factors that we need to consider in our product development to continue to manufacture the most desirable and competitive mill drill machines.

Table of Contents

In our experience there are three highly significant factors that influence changes in mill drill technology and manufacturing. Two arise from new material technologies, both as manufacturing challenges for existing mill drill technologies to overcome, and as solutions in the development of new cutting tool materials and technologies.

What are 3 significant influences on modern mill drill technology?

- New material technologies

- Changes in cutting tool design

- Demand for improved User Experience

The third significant influence is the expectation of modern mill drill customers that tools, machines and equipment will be highly functional, fit for purpose, and easy to use. We can summarize this last point as an increasing demand for excellence in User Experience (UX), which has become common across all modern industries and products.

How do new material technologies affect mill drill design?

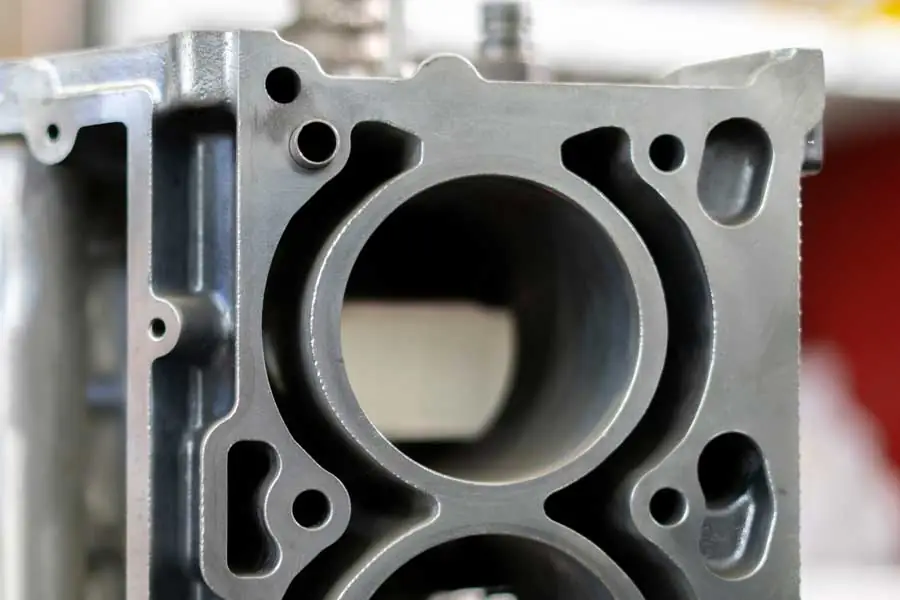

Many industries have experienced a significant increase in advanced alloys and in carbon fiber reinforced plastics (CFRP) manufacturing. CFRP is the most recent material technology to have an impact on mill drill design. Advanced alloys and composite materials are a technological challenge to mill drill manufacturers because of their hardness and temperature sensitivity, and the fibrous, abrasive composition of CFRP adds the challenge of increased wear on cutting tools.

What are 3 ways cutting tool & material technologies affect mill drill design?

- Minimizing frictional wear on cutting tools

- Preventing tools binding in the workpiece

- Reducing heat damage to cutting tools or workpiece materials

Carbide milling cutters are often used to cut advanced alloys and CFRP for these reasons, but success requires precise control of feed rates, cutting speed and coolant supply. Reliable coolant supply is especially important for CFRP because the melting point of the binder is a limiting factor for cutting speed. CFRP binders require careful temperature control during cutting because the structural strength of the material can be affected at temperatures that are well below the melting point of the binder.

Frictional wear on cutting tools, binding during cutting and heat damage to the workpiece are challenges that every mill drill manufacturer has to take into account in mill drill design no matter what material is being cut, but which are significantly greater problems with some alloys and with CFRP milling and drilling. The solution is to offer mill drills that have precision variable speed controls and excellent cooling and lubrication systems.

What is the influence of cutting tools on mill drill technology?

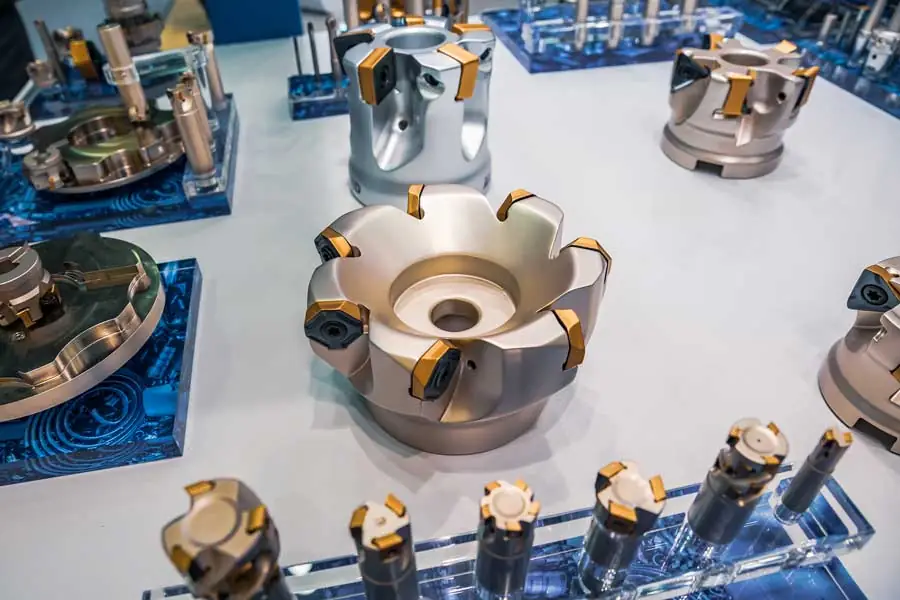

Indexable inserts have become an important tooling option for mill drills, with early innovations by companies such as Sandvik and Emuge Franken now made mainstream by other cutting tool manufacturers. This has made the price point of indexable insert cutting tools affordable even for small workshops.

What are 3 ways Rong Fu maximizes mill drill cutting tool compatibility?

- OEM & ODM options for different tool holder configurations

- Customizable feed & speed controls

- Choice of motor and gearing types

Mill drill technology has to keep pace with cutting tool innovation, which is why Rong Fu offers a diverse catalog of mill drill designs including feed and speed options suitable for all types of cutting tool including indexable inserts and specialist tools used for specific industrial applications, like the slow speed carbide tools used for composite and carbon fiber reinforced plastic (CFRP) manufacturing.

Another consideration is the changes in chuck and tool insert technologies to accept new generations of cutting tools. Mill drill manufacturers like Rong Fu need to offer options for different types of milling tool holders in OEM and ODM designs to enable customers to make full use of the best innovations in cutting tool technology for their specific market sectors.

Why is user experience important in mill drill design today?

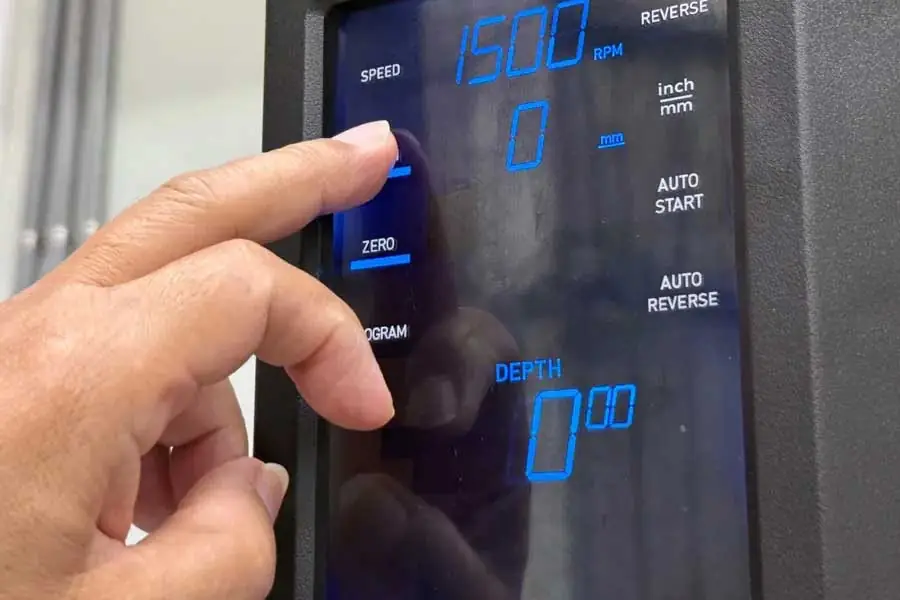

he touch screen panel shown above is an example of a contemporary Rong Fu mill drill interface design focused on user experience. Modern customers for mill drills and other workshop machinery have technological sophistication and ease of use built into their everyday life experience. A generation who have been raised with the convenience and connectedness of smart phones and social media expect something more than simple switches, buttons and knobs from modern mill drill machines.

How does Rong Fu mill drill technology improve user experience?

- Customer surveys identify functions to develop or improve

- Maintaining expertise and capabilities in new & emerging technologies

- Working with OEM & ODM mill drill clients to enhance styling and appeal of products

User experience (UX) includes the functional ease of use as well as the conceptual design and impressions that come from user interactions and experiences of technology. At Rong Fu our approach to UX includes surveying customers to identify strengths and weaknesses for design refinement, inclusion of new standard technologies like touch screen interfaces, and award winning attention to styling and design features.

Rong Fu are experts in mill drill technology & product development

Rong Fu are experts in OEM and ODM mill drill technology, innovation and product development because we have spent more than 50 years designing and refining metal cutting bandsaws and mill drill machines for our global customers to meet the challenging demands of changes in markets and global economies.

At our factory in Taiwan the Toyota Production System maximizes our production efficiency and quality management, and includes the capacity for parallel production of a range of different models of mill drills for mixed batch shipments in any order size.

Our expertise gives you the opportunity to offer a range of high quality, feature-rich ODM mill drill machines without the development costs of maintaining your own innovation team. Contact us to discuss how working with Rong Fu gives you ISO certified globally compliant ODM and OEM mill drill options that keep your brand on top of the game.