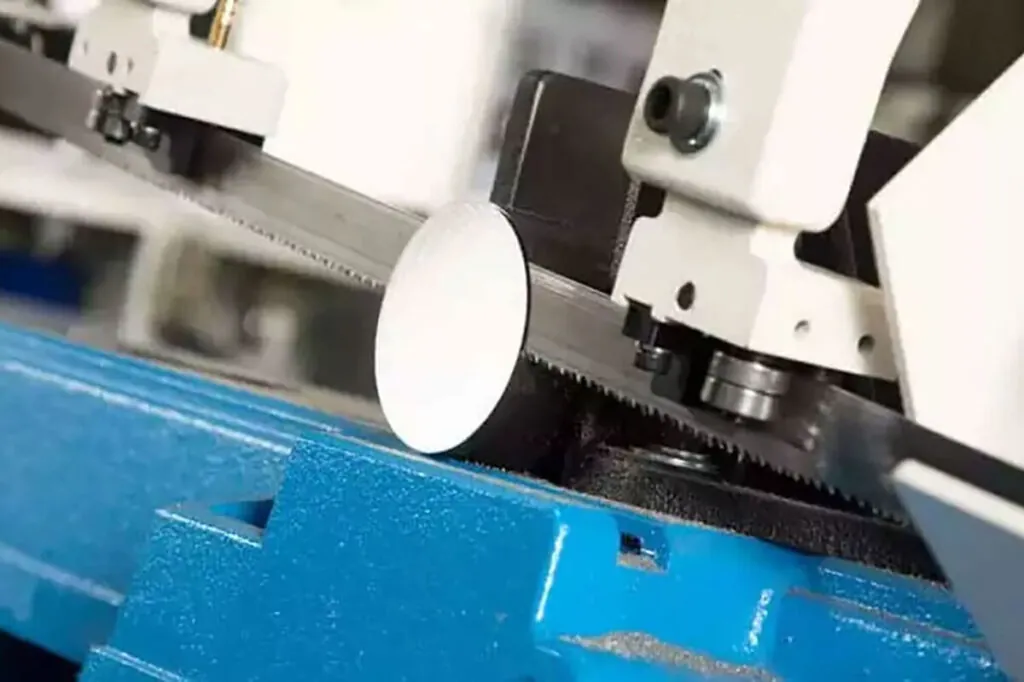

Definition of Carbide Blade Inserts

Why It Matters for Band Saw and Mill Drill Machines

Related Terms

Band Saw Blade Break-In Band Saw Tooth Pitch Band Saw Kerf Band Saw Tension Adjustment Band Saw Blade Set Pattern Band Saw Guide SystemFAQ

How do Band Saw Carbide Blade Inserts affect cutting speed?

Band Saw Carbide Blade Inserts allow significantly higher cutting speeds compared to standard steel teeth due to their extreme hardness and heat resistance. In industrial metal cutting, operators can increase surface feet per minute (SFPM) without excessive tooth wear. This makes carbide inserts particularly effective when cutting hardened steels or heat-resistant alloys where slower speeds would otherwise be required. However, proper feed rate adjustments and coolant application are critical to avoid chipping the carbide edges.

Are Band Saw Carbide Blade Inserts suitable for all materials?

Band Saw Carbide Blade Inserts excel in cutting abrasive or hardened metals but may not be optimal for softer materials like aluminum or mild steel, where standard high-speed steel blades are more cost-effective. Carbide-tipped blades can overcut softer materials due to their aggressive edge, and the higher cost of carbide is not justified in low-wear applications. Operators should match blade type to material hardness and production requirements.

What signs indicate replacement of Band Saw Carbide Blade Inserts?

Common signs include chipped or missing carbide tips, uneven tooth wear, excessive vibration during cutting, and visible scoring on the workpiece surface. A decline in cutting speed without feed rate changes is another indicator. Running a blade with damaged Band Saw Carbide Blade Inserts can cause increased friction, heat buildup, and damage to both the blade body and the workpiece. Prompt replacement prevents further operational issues.