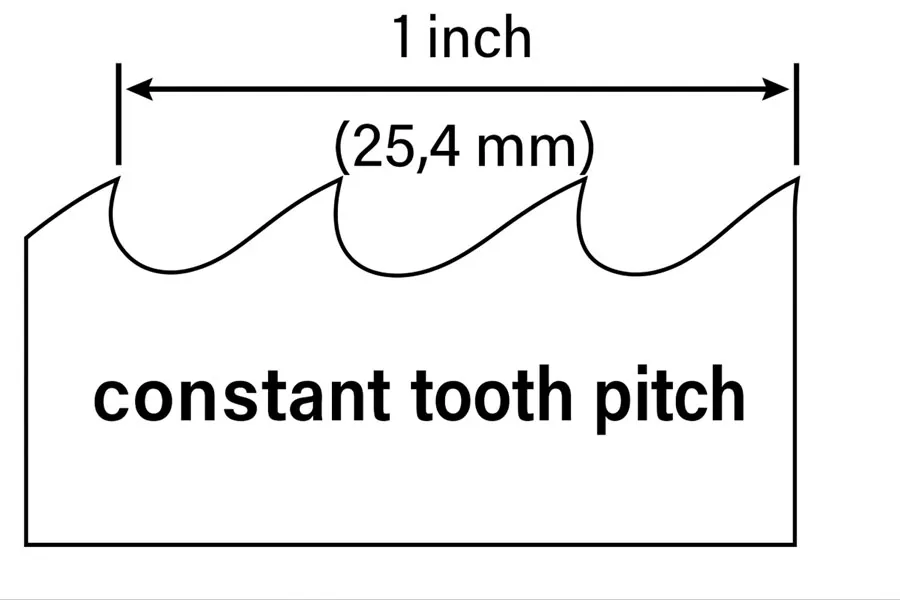

Definition of Constant Tooth Pitch

Why It Matters for Band Saw and Mill Drill Machines

Related Terms

Variable Pitch Hook Tooth Skip Tooth Raker Tooth Tooth Pitch Chip LoadFAQ

In which applications is constant tooth pitch preferred?

You’d choose constant tooth pitch for simple, straight-line cuts and when material hardness is uniform. It’s common in wood cutting, non-ferrous metals, and basic steel sections. In mill drilling, constant pitch end mills excel at slotting and shallow face milling where repeatable chip load and surface finish consistency matter. If you run batch parts of the same geometry and material, constant pitch lets you dial in a single feed rate and expect identical results every run.

How does constant tooth pitch affect cut quality and surface finish?

With constant tooth pitch, each tooth removes the same chip thickness, so you get a consistent feed per tooth. That yields uniform cutting forces and minimal tool deflection. The result is an even surface finish without ridges or burn marks. You also reduce the risk of one tooth doing extra work and wearing prematurely. This steadiness translates into smoother surfaces and fewer secondary finishing operations, which saves you time and reduces operating costs.

Are there any drawbacks to using constant tooth pitch tools?

Constant tooth pitch tools can amplify machine-induced vibrations or resonance, especially in rigid or hard materials. You might see chatter marks if the natural frequency aligns with your spindle speed and feed. Variable pitch tools can mitigate that. Also, constant pitch may not adapt well to mixed-material cuts or complex contours. If you need to reduce noise and vibration in those cases, consider a variable pitch or mixed geometry cutter instead.