Definition of Band Saw Blade Speed Range

Why It Matters for Band Saw and Mill Drill Machines

Related Terms

Material Compatibility, Band Speed, Variable Frequency Drive, Feed Rate, Chip Formation, Blade SelectionFAQ

What blade speeds are supported on industrial band saws?

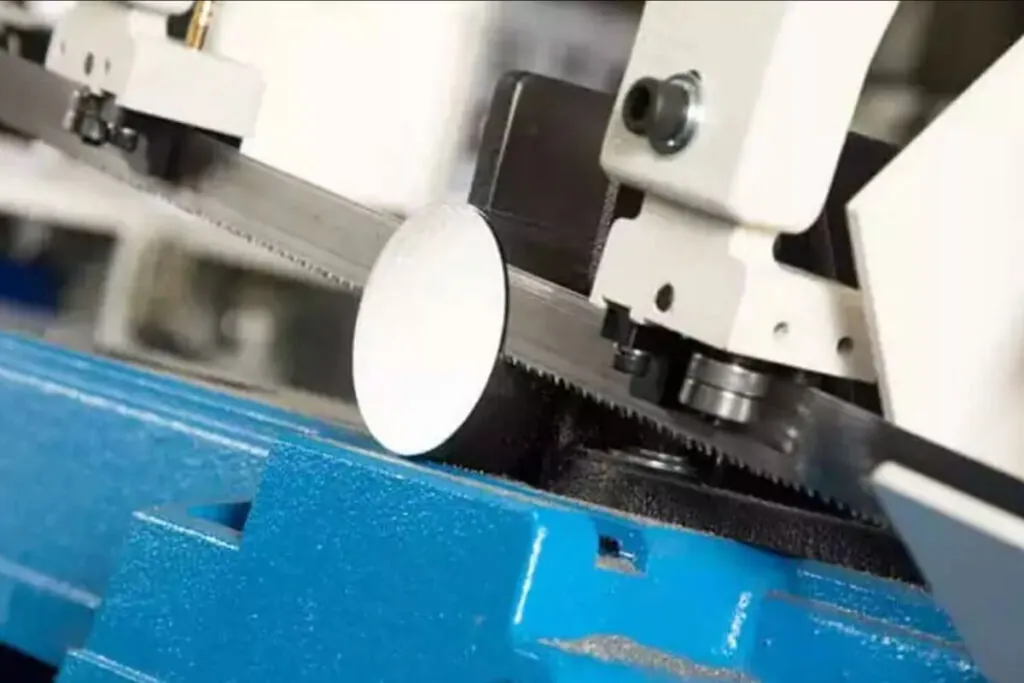

Industrial band saw blade speed range typically spans 50-350 SFPM for standard metalworking machines, with high-speed models extending to 500 SFPM or higher for non-ferrous applications. Entry-level machines offer limited ranges of 100-250 SFPM through stepped pulley systems with 3-4 fixed speeds. Production horizontal saws feature variable frequency drives providing infinite adjustment throughout the operating range. Specialized high-production machines for aluminum and brass achieve speeds exceeding 1000 SFPM. Low-speed capability below 60 SFPM proves essential for cutting titanium, Inconel, and other heat-sensitive alloys. Selecting appropriate blade speed range requires matching anticipated material mix to available machine specifications.

How do operators determine correct blade speed for specific cutting applications?

Determining correct band saw blade speed requires evaluating material properties, blade specifications, and desired outcomes. Start with published cutting speed charts specifying SFPM recommendations by material grade. Carbon steels typically cut at 200-300 SFPM, stainless steels at 80-150 SFPM, and aluminum at 500-1000 SFPM. Adjust base speeds downward for larger cross-sections, harder tempers, or difficult geometries. Increase speed for smaller workpieces and softer grades. Monitor chip color and formation as feedback indicators, with blue chips indicating excessive speed generating harmful heat. Optimal blade speed produces consistent silver-colored chips without burning or welding. Document validated speeds for repeat applications to eliminate trial-and-error adjustment time.

What maintenance ensures consistent band saw blade speed range accuracy?

Maintaining band saw blade speed range accuracy requires periodic calibration and component inspection. Variable frequency drives need parameter verification annually to ensure commanded speeds match actual blade velocity. Belt-driven systems require tension adjustment and wear inspection to prevent slippage that reduces effective speed. Measure actual blade speed using tachometer or strobe light comparison against control panel readings. Gearbox transmissions need oil level monitoring and gear wear assessment. Worn drive components create speed variation that affects cut quality consistency. Electrical supply voltage fluctuations alter motor speed on VFD-controlled machines. Installing power conditioning equipment stabilizes speed accuracy in facilities with variable electrical quality. Tracking speed accuracy during preventive maintenance identifies degradation before production quality suffers.