Definition of Band Saw Cutting Tolerance

Why It Matters for Band Saw and Mill Drill Machines

Related Terms

Blade Deflection, Frame Rigidity, Repeatability Accuracy, Blade Tension, Guide Alignment, Feed RateFAQ

What cutting tolerances can an industrial band saw achieve?

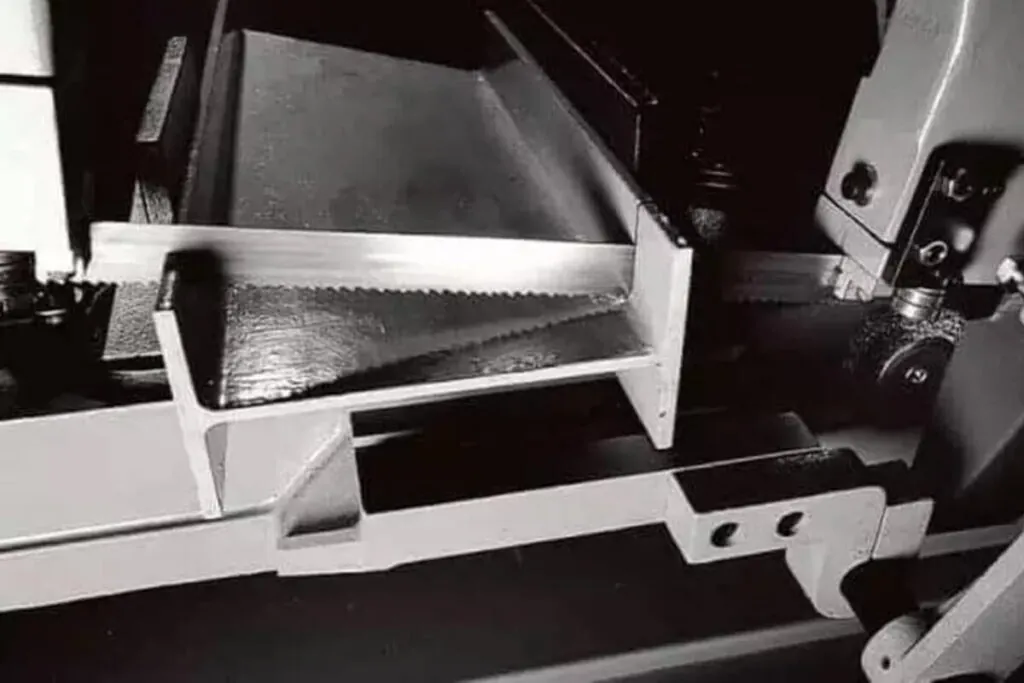

Industrial band saw cutting tolerance capabilities vary based on machine class and configuration. High-precision horizontal band saws with rigid frames and quality blade guides achieve tolerances of ±0.005 to ±0.010 inches on ferrous materials. Standard production band saws typically maintain ±0.015 to ±0.025 inches under normal operating conditions. Factors affecting tolerance include blade condition, proper tensioning, guide wear, hydraulic feed stability, and material consistency. Achieving tighter tolerances requires slower feed rates, premium bi-metal or carbide blades, and regular maintenance intervals. Operators should verify tolerance capabilities through test cuts when precision requirements exceed ±0.020 inches.

How does blade wear affect band saw cutting tolerance over time?

Blade wear progressively degrades band saw cutting tolerance as tooth geometry deteriorates. Dull teeth require increased feed pressure, causing blade deflection and dimensional variation. Tooth set wear reduces kerf width consistency, producing cuts that wander from the intended line. Gullet damage from chip welding creates irregular cutting forces that translate to surface waviness and tolerance loss. Most production environments observe noticeable tolerance degradation after 50-70% of blade life. Implementing scheduled blade changes based on cut area rather than time prevents gradual quality drift. Tracking tolerance measurements against blade runtime establishes reliable replacement intervals for specific material applications.

How should operators verify band saw cutting tolerance during production runs?

Verifying band saw cutting tolerance requires systematic measurement at defined intervals throughout production. Operators should measure cut dimensions using calibrated calipers or micrometers on representative samples, typically every 20-50 pieces for critical applications. Recording measurements identifies tolerance drift before parts exceed specifications. Compare results against established process capability data to detect abnormal variation. Check both ends of longer cuts to identify blade deflection or feed issues. Environmental factors including coolant temperature and ambient conditions affect tolerance stability. Implementing statistical process control charts provides visual tracking of tolerance trends and triggers corrective action before producing nonconforming parts.