It is essential to clean and lubricate your Rong Fu mill drill machine to keep friction and heat under control. This is the key to efficient, effective cutting and extending the life of your mill drill and your cutting tools. Frictional heat is the enemy of all mechanical cutting processes. You can’t avoid some heating effects from cutting, but you can keep them under control by keeping your mill drill clean and lubricated with an uninterrupted flow of coolant.

Table of Contents

What happens if you don’t clean and lubricate your Rong Fu mill drill machine?

Failure to clean and lubricate your Rong Fu mill drill machine as part of your routine mill drill machine care and maintenance schedule causes increased friction and wear to cutting tools and machine components. There are four main factors that significantly increase frictional effects on your mill drill machine and which require specific attention to cleaning and lubrication procedures.

What are the 4 main problems in mill drill operation caused by poor maintenance?

There are 4 main problems in mill drill operation that are caused by poor cleaning and lubrication maintenance, and they are all easy to avoid if you have a Rong Fu mill drill by following an easily managed routine that is provided in the operating manual.

- Metal chips, splinters & swarf build up on workpiece & tools

- Dust & workshop contaminants in lubricants

- Lubrication & coolant deterioration

- Corrosion & rusting of unprotected components

Mill drills that are manufactured by innovative, experienced, customer focused companies like Rong Fu are designed for ease of use. Our mill drills have accessible lubrication points, easy changing and maintenance of coolant systems and customization options like quick release clamping systems, which make it much easier to remove the workpiece rapidly and brush off any metal chips without forcing contaminants into the vice mechanism.

Metal chips, splinters & swarf need to be cleared

The smallest and sharpest cutting chips, metal splinters and swarf can end up embedded in the lubrication of chucks, spindles and gears as well as easily getting caught in the moving parts of your vice and clamps. This can dramatically increase wear on the moving parts of your mill drill machine and reduce precision. This is why you must ensure cutting chips and swarf are effectively cleared from the work area during cutting tasks. Keyless chucks are a good option for your Rong Fu mill drill for easier cleaning.

Contaminants reduce the effectiveness of lubrication

Fragments of metal in the grease and oils that you use to lubricate your mill drill machine are only one part of the picture for the breakdown of lubricants. Oils and greases tend to absorb dust and contaminants from the environment, and workshops are very hard to keep completely clean. Some lubricants are hygroscopic and will absorb water, causing emulsification and reducing their effectiveness.

Lubricants & coolants do not last forever

The combination of environmental contaminants reduces the lifespan of your machine lubrication, which is why you need to pay careful attention to following manufacturer maintenance schedules for changing oils, cleaning and greasing spindles, chucks and gears. Lubricants and coolant do not last forever, and their effectiveness reduces over time, and this can have a significant impact on cooling and wear if you do not change them within the recommended maintenance period.

Keep your mill drill components protected from corrosion

Another important reason to maintain lubrication is the potential for components to corrode, usually through rusting of ferrous machine parts. This is easily prevented by maintaining a light film of oil on exposed surfaces, and can be done with a soft cloth with some light oil added to it. Do not put oil on touch screens or plastic surfaces, however, unless the machine manual states it is safe to do so.

How does mill drill cutting technique affect cleaning & lubrication?

As you cut and shape a workpiece with your mill drill, this creates metal chips and swarf. The size and shape of the chips and swarf depends on the material being cut, the condition of the cutting tool, and the cutting speed and temperature. A well maintained cutting tool with correct lubrication and cutting speed will tend to generate clean, curled chips that are easy to clear from the working area.

What are the three key maintenance activities for cleaning & lubricating your mill drill correctly?

There are three specific maintenance activities that will keep your mill drill clean and well lubricated to minimize friction and extend the life of your machine and cutting tools. If you follow these procedures you will also increase the precision and efficiency of cutting with your mill drill, and the time saved by improving cutting efficiency more than compensates for the time spent on maintenance.

- Clearing & cleaning your tooling & working area after every cutting operation

- Maintaining grease & oil lubrication of moving parts to a high standard

- Ensuring free flow of clean cooling lubricant for every cutting task

Clearing & cleaning your tooling & working area after every cutting operation

It is tempting, especially if you have a number of urgent or repetitive cutting tasks to do, to just reset your machine, clamp a new workpiece in the vice and start cutting again immediately after finishing the last piece. As a minimum you should always brush off and wash down with lubricant after every cutting task is finished, ensuring that all visible chips and swarf are removed from the cutting area, tooling, vice and clamps.

Maintaining grease & oil lubrication of moving parts to a high standard

Your mill drill will have recommendations for when to change oils and grease moving parts. If you are working in a particularly humid or dusty environment you may need to make changes more frequently, likewise if you work your machine hard. It’s a good idea to carry out visual inspection of surfaces and check lubricant condition regularly between changes in case you need to reduce the time between changes. You should always use the recommended lubricants and not attempt to save on costs by using lower grades, as this is a false cost saving if it leads to wear and damage to expensive components.

Ensuring free flow of clean cooling lubricant for every cutting task

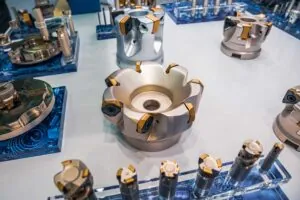

Cooling lubricant is your friend, keeping the cutting tool and workpiece cool while removing chips and swarf from the working area, cutting tool and faces being cut. The correct cooling lubricant is essential if you are cutting aluminum alloys or stainless steels. Keep mill drill coolant clean,and ensure directional coolant heads are aimed at the correct point to maximize both cooling and chip clearance. Many Rong Fu mill drills can be customized with the coolant system shown above, which is simple to install and set up.

What is the cleaning and lubrication procedure for Rong Fu mill drill machines?

- Turn off the power, unplug or lock out the mill drill machine circuit depending on your installation

- Remove loose chips and dirt with a soft brush, compressed air or vacuum cleaner

- Clean the body of the machine, table, vice and clamps with a cloth and suitable degreaser

- Carefully remove any swarf and burrs from the chuck

- Use a dry cloth to dust motor and electrical box housings

- Check and clean the cooling system filter, tank and lines if necessary

Identify lubrication points indicated in the manual. These may include spindle and gearbox reservoirs and the locations at which you apply oil to lead screws, guides and clamps. Verify that oil reservoirs are full to the recommended level and change if the oil is not clear.

Lubricate all other moving parts including the column, column rack and feed, remember you need to lubricate both the powered mill drill cutting elements as well as the manually operated clamping and feed components. Check for smooth movement of manual components to verify correct lubrication.

Rong Fu mill drill machines are designed to be easy to maintain

Some mill drill machines are better designed than others to be easy to maintain, including routine adjustments, cleaning, oiling and greasing. Neglecting to clean and lubricate will reduce the service life of your mill drill machine and cutting tools. We know that at the end of a working day, you might not want the added burden of a difficult, time-consuming cleaning and lubrication schedule, and this is why Rong Fu mill drill machines are designed to be convenient to maintain.

When you choose a Rong Fu mill drill machine, you will find the maintenance procedures are user-friendly, based on our long experience of designing and manufacturing workshop machines, and you can expect decades of service from Rong Fu mill drills. Contact us to find out more about our award winning range of mill drill machines that are designed to deliver convenient, easily maintained precision.