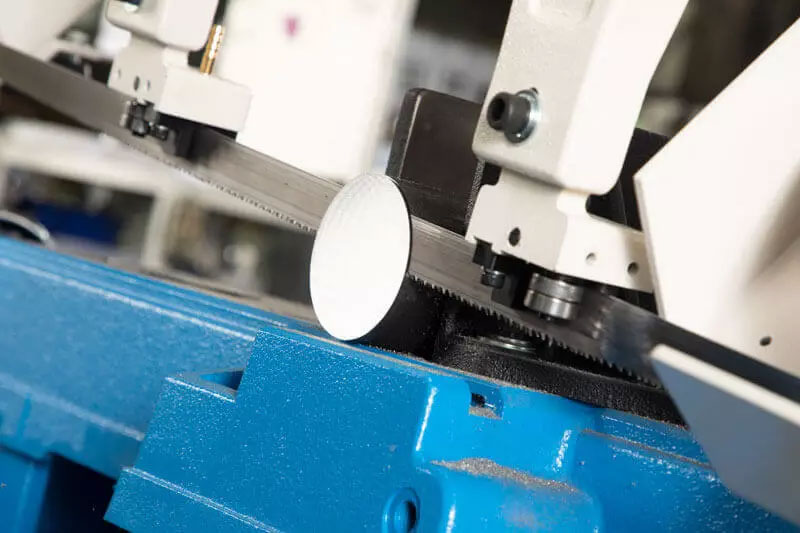

People think about adding a horizontal band saw to their workshop when they are spending a lot of time cutting metal with hand-held tools. A metal cutting bandsaw delivers continuous cuts by driving a band of metal with sharp cutting teeth tensioned between two wheels. A metal cutting bandsaw speeds up routine cutting tasks enormously.

Table of Contents

Do You Need A Horizontal Band Saw?

If you notice how much time and effort you spend cutting metal in your workshop then you should definitely consider purchasing a metal cutting horizontal band saw. There are other options for cutting metal, including plasma or gas cutters, laser cutters, hand-held and bench mounted disk cutters and the good old fashioned hacksaw.

Plasma, Gas & Laser Cutters

Other cutters have good and bad points to consider. Plasma & gas cutters can often be purchased quite cheaply in manual versions, but are not very accurate and present significant fire hazards. Automated plasma and gas cutters, as well as laser cutters, are very expensive and require careful maintenance.

Disk Cutters & Hacksaws

Disk cutters and hacksaws are effective for simple straight cuts, but hacksaws are very hard work for all but the shortest cuts, and disk cutters tend to melt edges, create a lot of sparks and can cause serious injuries if mishandled.

Metal Cutting Horizontal Band Saws are the Cost-Effective Option

The metal cutting band saw is a reliable, consistent, safe and cost-effective machine. You can select a bandsaw to match the size of your most common tasks from small benchtop versions to industrial machines that can only be moved by cranes. Metal cutting band saws have two types to suit different metal cutting needs, and can be customized with a range of optional features.

Horizontal or Vertical Metal Cutting Band Saw?

The two standard types of metal cutting bandsaw are horizontal cutting and vertical cutting bandsaws. To decide which one is best for you it is important to consider the type of cuts you need to make. It’s possible you might need both a vertical and horizontal metal cutting bandsaw to fully equip your workshop!

The Difference Between Vertical & Horizontal Metal Cutting Band Saws

The blade in vertical metal cutting bandsaws is mounted in a fixed position that you feed your material through to make cuts. Horizontal cutting bandsaws have a blade that is mounted on a mobile arm that is used to pass the blade through the material, which is clamped in position for cutting.

Uses of Vertical & Horizontal Metal Cutting Band Saws

For curve and scroll cutting in sheet metal, a vertical metal cutting bandsaw is a cost-effective way to get good results. If you are cutting a lot of metal from stock, perhaps sections of flat bar, rod or pipe, then a horizontal metal cutting bandsaw will speed up the process and make it easier to achieve uniform results.

Features of Metal Cutting Band Saws

Now you’ve decided you need a metal cutting bandsaw, it’s important to consider the features that you need in your bandsaw. There are a wide range of options and accessories available for metal cutting bandsaws as well as standard features that you should expect to find in a good quality bandsaw.

What You Should Find Included With A Horizontal Bandsaw

These are standard options that most good quality metal cutting bandsaws will be equipped with out of the box.

- Blade Covers & Safety Features

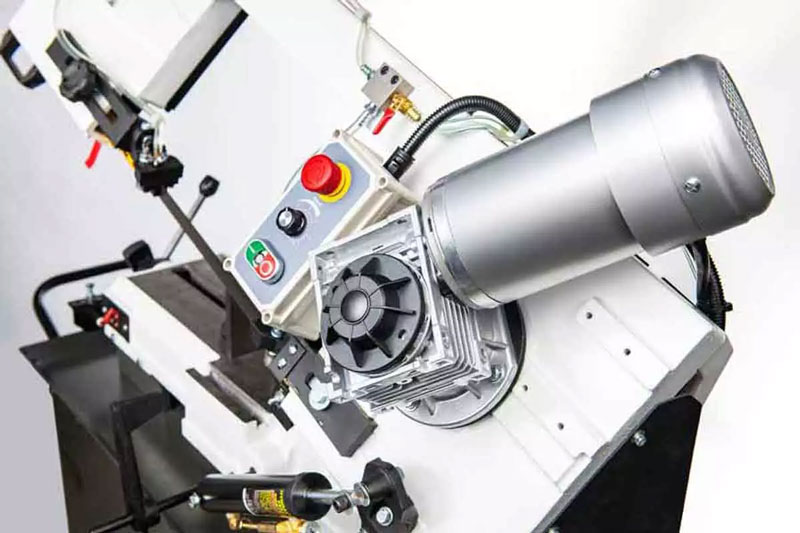

- Precision Gearing & Motor Control

- Chip Removal System

- Blade Guides

These do not need to be complex or expensive features, a chip removal system might use brushes that are fitted alongside the blade guides, for example. DC motors are included here even though they are not absolutely essential, and may add a little to the price, because they are much more cost-effective and efficient than AC motors.

Desirable Optional Features For Metal Cutting Bandsaws

An attraction of horizontal bandsaws is that they can be easily customized for your own specific tasks by adding optional equipment and features.The following features of metal cutting bandsaws are commonly available as add-ons to basic machines.

- Hydraulic Downfeed Controls

- Variable Speed Motors

- Swivel Heads

- Coolant Systems For Wet Cutting

- Adjustable Blade Guides

- Energy Saving DC Motors

- Stepped Pulleys For Rapid Speed Changes

- Adjustable Cutting Angles

Look to see if your choice of metal cutting band saw is either equipped with any of these features as standard or if they are optional extras. Most of these are optional features of horizontal metal cutting bandsaws, but coolant systems, pulley and motor configurations also apply to vertical metal cutting bandsaws.

Manufacturers of Horizontal Band saws

The quality of a metal cutting bandsaw depends on the expertise, experience and quality management systems of the metal cutting bandsaw manufacturer. When choosing a metal cutting bandsaw it’s important to get a feel for the expertise and quality standards of the manufacturer as these limit the quality and reliability of the bandsaws they manufacture.

Quality Standards For Metal Cutting Bandsaws

Many metal cutting bandsaw manufacturers claim high quality standards and performance for their products, but without external certification or calibration and testing data you can’t be certain that the machines they supply will live up to your expectations.

ISO 9001 & CE Certification For Metal Cutting Bandsaw Manufacturers

It’s a good idea to see if the manufacturer is certified to the ISO9001 quality standard and if their machines have CE Certification or equivalent for your local needs when you are choosing a metal cutting bandsaw. You should also look at their website to check their quality control processes.

Manufacturer Calibration & Testing of Metal Cutting Bandsaws

If a manufacturer includes calibration and testing data with each metal cutting bandsaw they ship it is a very good sign. This demonstrates that every machine has gone through a rigorous testing and quality assurance process.

Types of Horizontal Band Saw Manufacturer

Another consideration is whether the bandsaw you have chosen is being made by the supplier who is selling it to you, or if it is being manufactured for them by someone else and they are a reseller who is adding their brand name to it.

OEM Metal Cutting Horizontal Band Saw Manufacturers Offer Better Service

Why is this important? Think about what happens if your horizontal band saw develops a fault or if you have a technical issue or questions about good practices or features of your machine. The original equipment manufacturer will be able to answer your questions and provide rapid support, but a reseller will not have the technical expertise or experience to do this.

Rong Fu Horizontal Band Saws

We pride ourselves on the quality and reliability of our metal cutting bandsaws, and on the positive feedback we receive from our many customers. We build customer feedback into our design cycle to ensure we continuously respond to the changing demands of the marketplace.

- 40 Years Experience in Metal Cutting Bandsaw Manufacture

- In-House Design, Manufacture, Quality Control & Product Support

- Global Quality Certifications, Pre-Shipment Calibration & Testing

40 Years Experience in Metal Cutting Bandsaw Manufacture

As a very experienced OEM supplier of metal cutting bandsaws, we apply more than 40 years experience to designing and building a wide range of vertical and horizontal metal cutting bandsaws to suit almost any customer requirement.

In-House Design, Manufacture, Quality Control & Product Support

Rong Fu is a vertically integrated company, and we control all elements of metal cutting bandsaw manufacture from initial designs through production, quality control and customer service and support.

Global Quality Certifications, Pre-Shipment Calibration & Testing

We are ISO9001 compliant and manufacture our products to global standards, including European CE certification. We test and calibrate all our bandsaws before shipping to ensure they are ready to run ‘out of the box’ so our customers can have increased peace of mind.